Although electrostatic atomization is not a novel technique for painting, lately it has increased its implementation among industrial finishing companies, due to the most recently developed technologies. This article seeks to explain the concept, to which companies can help the most and how to implement it safely.

What is electrostatic atomization?

Electrostatic atomization is an industrial finishing process in which the paint jet or coating is applied by the action of an electric field. With this, the necessary forces are obtained for spraying the surface charges or the polarization of the liquid is achieved.

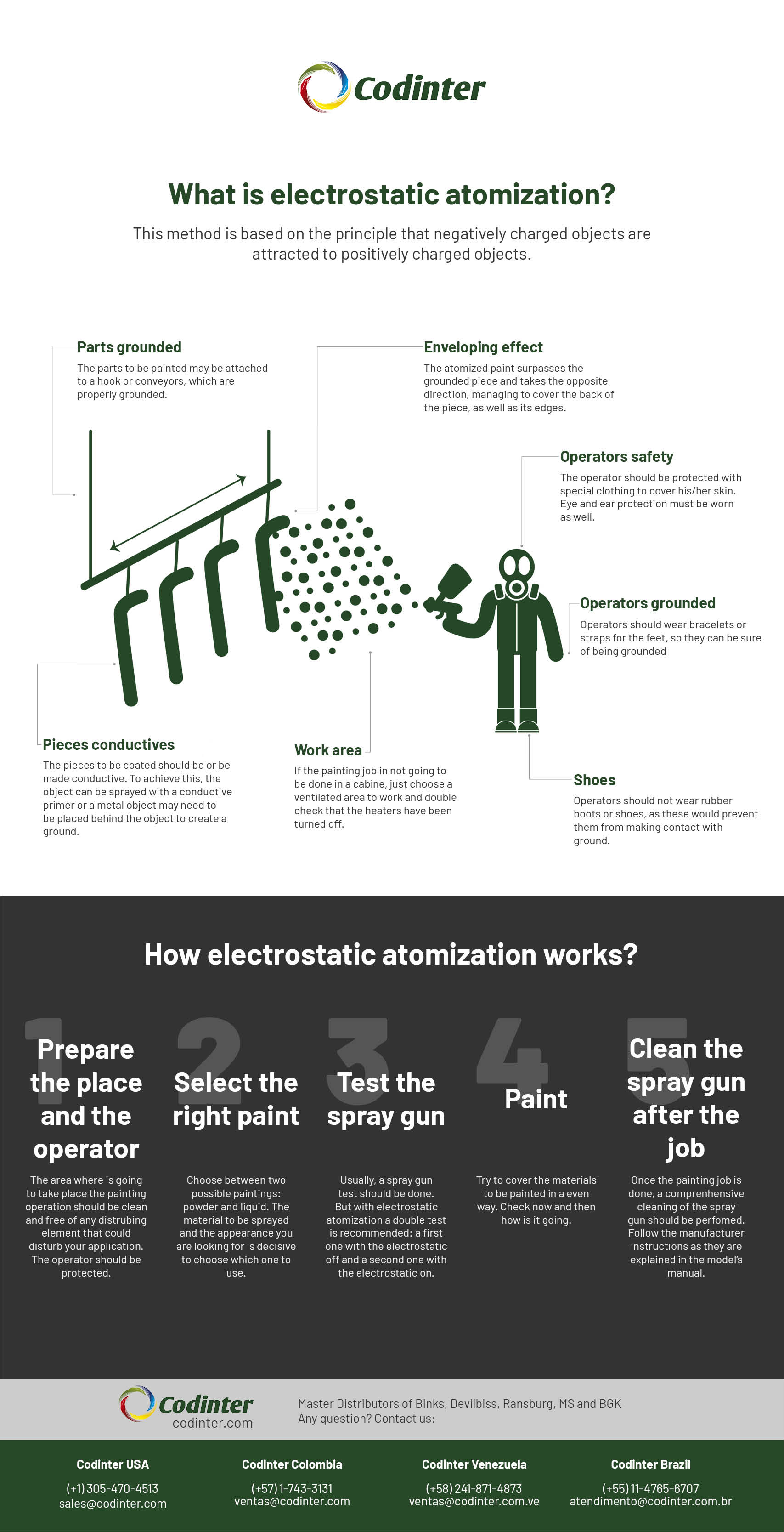

This method is based on the principle that negatively charged objects are attracted to positively charged objects.

An electric charge, generally negative, is applied to the coating material. The drops, negatively charged, are charged to the end of the spray gun by means of a charged electrode. Thus, they are pulverized and attracted to any grounded surface. Each particle receives a negative charge of 30-140 kV and 0-200 mA.

With electrostatic atomization, the enveloping effect can be achieved. In this one, the atomized paint surpasses the grounded piece and takes the opposite direction, managing to cover the back of the piece, as well as its edges.

With this effect the transfer efficiency is increased, which in some cases of electrostatic atomization reaches 98%. This results in lower paint costs, faster production, less cleaning and less VOCs.

Due the electrostatic charge, the paint particles, once sprayed, are less likely to stay in the air.

To achieve this, it is necessary that the difference of the charges is enough. In some pieces it can be seen how the paint mist envelops the object to be coated.

The pieces to be coated should be or be made conductive. To achieve this, the object can be sprayed with a conductive primer or a metal object may need to be placed behind the object to create a ground.

The electrostatic atomization can be added to any of the atomization techniques that exist, in order to improve the rate of product transfer.

For all electrostatic effect to happen, there must be always the presence of ground.

Advantages of Electrostatic Atomization

There is a lot of advantages when it comes to electrostatic atomization. Let’s number some of them:

- Covers a three dimensional objet, like tubular products, more evenly than any other atomization technology, because of the “wrap around” effect

- Also due the “wrap around” effect, save time because back sides can be atomized as front sides in a single movement

- Ensure the most even coat possible in the industry

- Saves painting because it have a higher transfer efficiency and material can be collected and reused

- Saves money by saving materials and time

- Can be use for spray pieces with complicated shapes

- Thickness of the coating can be adjusted to the desired finish

- Automatic operation can be used for high production speeds

- Is quick and easy to make color changes

- No preheating of the work pieces is required

- Thin substrates, such as metal sheets, can be coated easily

- Oven curing process, available in industrial finishing applications, results in a harder to remove and more durable painting

- Better finish look, due a very uniform paint thickness

YOU CAN BE INTERESTED IN: Spray guns: All about its use, parts and types

Disadvantages of Electrostatic Atomization

Despite all the benefits electrostatic atomization have, some disadvantages should be mentioned, such as:

- Higher film build on outside corners, due increased electrostatic attraction in that sectors

- Lower film build on inside corners, due limited electrostatic attraction in that sectors

- Material to be sprayed should be conductive o made conductive in order to fitting bonding

- Is very important objects to be sprayed are connected to ground, to avoiding safety or fire hazards

- Spray guns can be more delicate than regular ones, so they will need proper care

Can electrostatic atomization be used for wood and plastics?

Absolutely yes! However, a primer must be placed or make parts conductive in some way so that the electrostatic effect can work.

In a nutshell, in order for electrostatic effect to take place in wood, plastic, as well as in any other surface, 2 conditions must be met:

- The pieces have to be conductive (or have a way of transport electrons in its surface) with really low resistance to flow electrons

- The pieces have to have a ground potencial or stay connected to ground, for the pulling force to occur. So, for the part to spread, a pulling force has to be conductive

Is important remmember the basic principle of electrostatic which is: In order to paint an object with a coating charged negatively with an electrostatic field, the part has to have a conductive surface to allow its electrons to flow in search for ground, and the part has to be physically attached to a ground potential.

How electrostatic atomization works?

Although the name “electrostatic atomization” makes it seem a very complicated process, it is actually simple to apply it in most industrial finishing companies.

Actually, this atomization technology can be applied to many of the others, like Airless, Airless Assited, etc, to obtain a better finishing and save both material and time.

Let’s put it in 5 simple steps:

Step 1: Prepare the place and the operator

The area where is going to take place the painting operation should be clean and free of any distrubing element that could disturb your application. A closed cabine would be ideal for this kind of industrial finishing applications.

If the painting job in not going to be done in a cabine, just choose a ventilated area to work and double check that the heaters have been turned off.

If certain areas of the pieces should not be painted, drop cloths or put tape to protect them from painting.

The operator should be protected with special clothing to cover his/her skin. Most industrial finishing products brands have developed protection outfits for operators. Eye and ear protection must be worn as well.

A word of warning for operators: never point the spray gun to any person. The high pressure of the jet could hurt to the people.

Step 2: Select the right paint

When it comes to electrostatic atomization there are two possible paintings: powder and liquid. The material to be sprayed and the appearance you are looking for is decisive to choose which one to use.

Powder coating is named this process when you use powder as your painting of choice. After choosing the painting, load it in the tank or deposit you are going to use.

Step 3: Test the spray gun

No matter what atomization technology are you using, a spray gun test should be done. But with electrostatic atomization a double test is recommended: a first one with the electrostatic off and a second one with the electrostatic on.

To make this, the first step is turn on the spray gun and prime the pump to use. When testing, as always, check that the fan pattern is even.

Once you have completed the first test, turn the electrostatic on and test again. You should see the expected distribution of the painting in both cases.

Perform this test will help the operator to not make mistakes when painting and get the job done easy and faster.

If anything was wrong in any of this two tests, check what could be happening. But if everything ran well, you will be ready to paint.

Step 4: Paint

Having all the previous steps done, is the right time to paint. Try to cover the materials to be painted in a even way. Check now and then how is it going.

If the appearance of the objects are not the expected, change the way you are painting them.

To be effective when painting, double check the following:

- Having a good paint load to the gun

- Having a good (and in a good condition) spray gun

- Having all the objects to be painted well connected to ground

- Being special careful when painting objects with complicated shapes

- All the pieces are conductive or have been made conductive

In some industrial applications, when using powder coating the pieces should get though an oven to complete the painting fixation. After that, the excedent powder can be collected and reused.

Step 5: Clean the spray gun after the job

Once the painting job is done, a comprenhensive cleaning of the spray gun should be perfomed. Follow the manufacturer instructions as they are explained in the model’s manual.

This step is very important to maintain the spray gun and other equipments in good conditions for a long time. Electrostatic atomization guns and equipment usually are expensive and delicate. So, clean them regularly is crucial to keep low costs in industrial finishing applications.

Is electrostatic atomization very complicated or dangerous for the operators?

Electrostatic atomization is not very different from any other type of atomization. The difference is that both the object to be painted and the operator must be connected to ground.

The parts to be painted may be attached to a hook or conveyors, which are properly grounded. Operators should not wear rubber boots or shoes, as these would prevent them from making contact with ground. They can also have bracelets or straps for the feet, so they can be sure of being grounded.

In any case, an electric shock when using electrostatic atomizing equipment can be similar to touch an old television screen when on. Now, if the charge continues for a long time and there is no discharge, a spark may occur.

That is why it is important that both the parts and the operators are always connected to the ground.

Industries that are most suitable for electrostatic atomization

The savings that come as a result of the use of electrostatic application technology can help practically any industry that requires industrial finishing solutions.

However, some in particular may have special relevance, such as the following:

- Aerospace industry

- Automotive industry

- Pharmaceutical industry

- Agroindustry

- Furniture manufacture

- Manufacture of pieces of metal, wood or conductive materials

- Naval sector

These industries can benefit from including electrostatic atomization because it would speed up their processes and reduce material consumption.

What can be painted using electrostatic atomization?

The suitables options are almost countless. So, for deciding whether electrostatic atomization is a good fit for a certain application, it depends mostly in the desired finishing and the speed of production required.

Here is a list of main uses of electrostatic atomization:

- Electronical components

- Automotive parts

- Pharmaceutical products

- Manufacturing products from several industries

- Industrial facilities

- Marina railings

- Stables

- Commercial and residencial spaces

- Fences of any kind

In some cases, electrostatic atomization offers the most perfect finish, making it ideal for the automotive, aerospace and electronic equipment manufacturing industries such as telephones, computers, etc.

Paint powder or liquid paint: Which one to choose for my industrial finishing application?

If a powder is used instead of a liquid, this process is called powder coating. It is commonly used on things like bike frames and metal file cabinets.

Both powder and liquid paint have advantages and disadvantages. It is best to evaluate both to determine which is most appropriate for your particular case.

The powder paint

The powder is widely used for matte colors, for small applications.

The powder paint is faster in the application, because in a single pass it makes the 3 layers that the liquid paint requires.

The powder is cheaper and loose less volatile objects in the atmosphere (voc) pollutants.

On the other hand, when painting with powder, it is necessary to make a lot of preparation to the metal. In addition, it requires an oven.

Powder painting requires an implementation (initial expenses) that is more expensive compared to other systems.

The liquid paint

The liquid is faster in online production.

To use liquid paint, it is necessary to make 3 passes: the primer, the base paint and the enamel.

If it is dried in the oven, liquid paint requires less temperature than powder paint.

In the video you can see someone using liquid paint.

Guns and Equipment necessary for electrostatic atomization

A typical configuration for electrostatic atomization could require a spray gun, an air regulator, a pump or tank, a fluid regulator, air hoses and valves.

The exact equipment you could need when using, for example, a Ransburg Ransflex for electrostatic atomization, it depends of what application you required, the speed and size of your production, and the finishing you need.

Let’s see more details about some of this equipment.

The guns

Several brands have developed spray guns for electrostatic atomization. Each one with different designs to achieve specific results for different applications.

Ransburg, the creator of electrostatic atomization have recently lanched a new spray gun: Ransflex.

This electrostatic atomization spray gun includes an applicator that operates by compressed air alone and utilises an air driven alternator coupled to a high voltage cascade assembly that is used to generate the electrostatic charge internally. This way there is not a need for an external power supply and cable.

Ransflex comes in two models: RX and RFX. Both of them are FM, ATEX and CSA global standards compliant.

This new electrostatic spray gun have a patented turbine provides vibration-free operation, which make it one of a kind. Also, impact-resistant engineered gun body materials and ergonomic fit, feel, balance and controls complete the equation.

Any company or person owning a Ransflex can have peace of mind, because have five-year warranty.

A wide variety of spray nozzles are available for use in electrostatic atomization. The nozzle that should be used will largely depend on the shape of the pieces to be coated and the consistency of the paint needed.

When painting irregularly shaped objects is convenient to use a round tip. In case of paint large flat objects, is better to use a flat tip adapter.

Besides the spray gun to use, tanks, pumps, regulators and other equipment may be required.

YOU CAN BE INTERESTED IN: Paint Pumps: types and uses in industrial finishing

Rotating Electrostatic Disks and Bells

In very specifical finishing applications, like automatic lines for automotive industry, rotating electrostatic disks and bells can be use effectively.

High-rotational-speed disks and bells can be suitable for applying high-viscosity, high-solids coatings (like 65% volume solids and higher) in electrostatic atomization operations.

Usually, industries that use rotating electrostatic disks and bells set them in a conveyor loaded with parts to be painted. Most times they are put in a horseshoe shape structure. Disks and bells can be used automatically or even manually, in fixed or reciprocating mountings.

Rotating electrostatic disks and bells works using both electrostatic and centrifugal forces to atomize the coating material.

The process is as follow:

- Paint is pumped into the center orifice of the rotating disk or bell

- Paint is pushed out by centrifugal force to the edge of the swift spinning disk or bell toward the pieces to be coated

- The high voltage concentrated in the disk or bell rim charges the paint droplets as they are getting out from the machine

- The coat is attracted to the surface of the parts to be painted due the opposite electrical charge

We look forward to give you all the information you need to help you make the best decision about what electrostatic atomization guns and equipment to buy. Feel free to contact us anytime.

In a few words

Implement electrostatic atomization in your company can be a way to save time and money. In addition, it reduces pollution.

Although it is true that a greater initial investment is required than the one for a conventional equipment, in a short time you get the return on investment.

You are most welcome to ask whatever you need to know to decide your purchase. Our experts not only can help you to define the equipment you would need, but also design how they can be assembled.

We regularly publish useful information for the industrial finishing industry. Subscribe here to our monthly newsletter to stay informed.

As a summary, we have done this infographic where you can easily see what is explained in this article.

Did you like this article? We invite you to comment. Do you have questions? Contact us or make them in the comments section and very soon we will be answering.

This Post Has 2 Comments

My name is Rudolf Kayirezi and a Zimbabwean by nationality. I want to start a painting business in Zimbabwe using electrostatic atomization as the painting method so i need you to send me a quotation of all the equipment i need to buy from your company so that will be able to start the business.

For sure! We will contact you asap to define what equipment you may need, according to your business plan.