Technological solutions

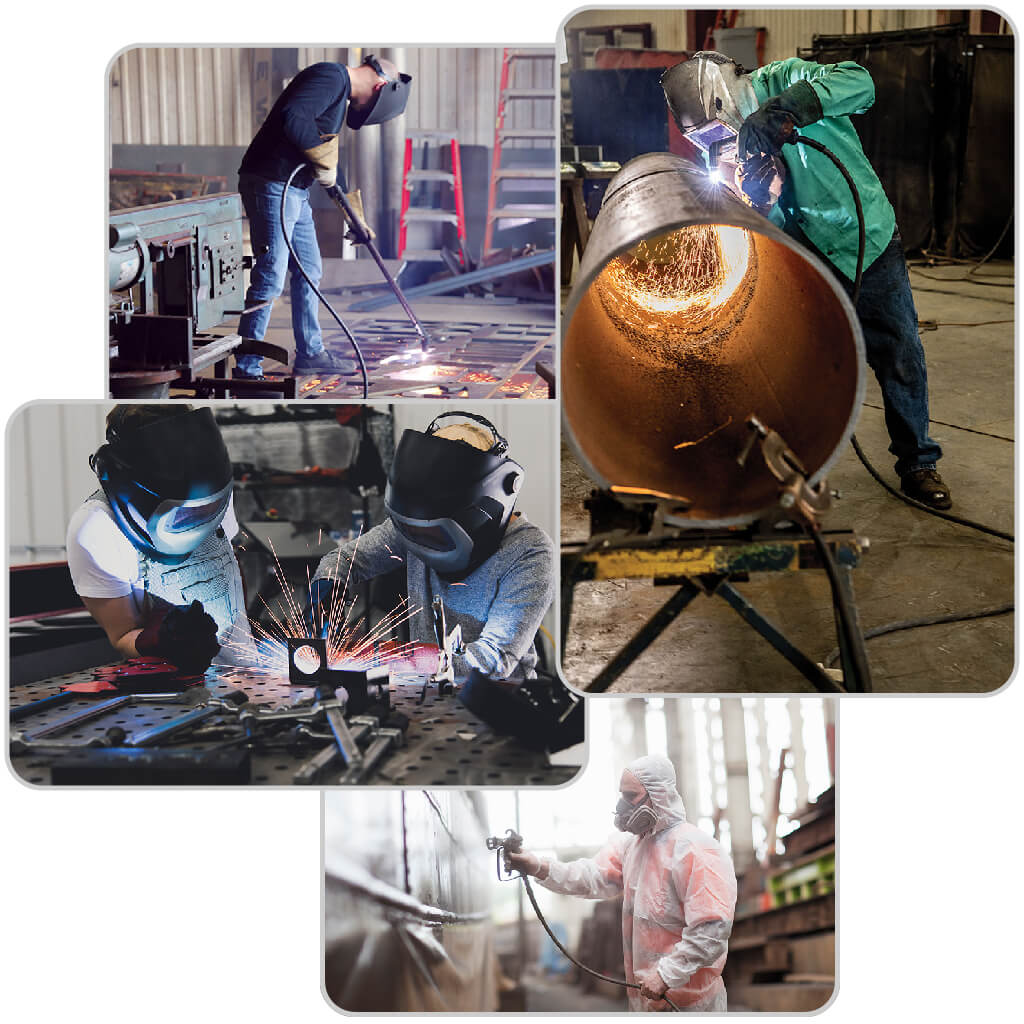

The best Welding, Cutting, Industrial Finishing and Automation Services in America

Codinter is not just a large company that is satisfied with selling products. Our clients need services that, with our decades of experience, we can provide.

That is why we have developed a series of services that can help our customers meet their needs and achieve their production goals more effectively and efficiently.

Equipment, Spare Parts, Accessories and Consumables for Welding, Cutting and more.

Codinter is your reliable supplier

Founded in 1979 in Colombia, the Codinter organization has not stopped growing and continuously improving. We fulfill our mission every day by offering high-quality, state-of-the-art welding, cutting, industrial finishing, and automation products to benefit the industries and communities in which we operate.

Services for the industries

Preventive maintenance of welding and cutting equipment

It is clear that it is never desirable to have delays or even the total stoppage of production due to a welding machine or cutting equipment that ceases to be operational. The best thing that can be done to avoid this is to give preventive maintenance to all your equipment.

The brands we represent have established maintenance parameters that we follow to the letter and for this reason, when carrying out preventive maintenance, we suggest the change of certain components that would be ready to fail due to use.

Depending on your work environment, it would be advisable to perform this maintenance two (2) times a year.

Services for the industries

Preventive maintenance of industrial finishing equipment

Industrial finishing equipment, such as guns, tanks, pumps, etc. they are exposed to heavy duty work all day and depending on the coating you are using, they could be subject to corrosion as well.

Performing preventive maintenance on industrial finishing equipment saves money and time. This prevents failures, thus preventing production from stopping unnecessarily. Manufacturers recommend a maintenance routine that we know well and know how to apply.

Part of the maintenance routine can be carried out at the end of each work period, by your own operators. We can provide you with training to implement this maintenance training, in order to extend the useful life of your equipment.

Depending on your work environment, it would be advisable to perform preventive maintenance two (2) times a year.

Services for the industries

Calibration of welding equipment

Through calibration, standard error margins (tolerance) are estimated for the correct operation of a welding machine.This is a certified service, carried out by professionals trained by the brands of welding equipment that we distribute.

When a welding machine is subjected to a calibration, a certificate is granted that ensures that said equipment is in optimal operation with its original factory power ranges. Said certification obeys quality and industrial safety standards and are required by many companies. Hence the importance of calibrating the equipment. In Venezuela, to cite an example, the calibration of welding equipment is a service certified and endorsed by SENCAMER. Other bodies regulate this process in each country.

At Codinter, our technicians are trained to carry out this calibration. This service does not take much time and can be done in any of our workshops.

A multinational company

Some Outstanding Numbers

We have arrived to stay. Our great performance throughout years and years of supplying companies around the world is our best recommendation.

Focused on our Clients

We develop solutions to increase the safety and profitability of our clients.

Local presence

We have a local presence in four countries: the United States, Colombia, Brazil, and Venezuela.

Services for the industries

Fault diagnosis and repair of welding and cutting equipment

Due to the fact that the machinery and equipment of your workshop or industry complement each other, if one stops, or is not operational, due to a malfunction, or due to the wear of some component, it could cause serious problems for your productivity. This could cause bottlenecks, delays, and possibly even a complete stoppage of work.

When that happens, we can help you. We have the training and experience to correct any anomaly until leaving your equipment as original from the factory. Our technicians have been trained directly by the equipment manufacturers.

We follow the procedures established by the brands to ensure that we quickly find the failure presented and determine the cause, in order to repair or update them, so that they can return to production shortly.

Services for the industries

Troubleshooting and repair of industrial finishing equipment

Since industrial finishing is often the final part of production, having a stop in this section of the line could cause delays in shipping orders to customers.

In the painting part, we provide corrective services in equipment such as manual and automatic paint guns, diaphragm, piston, and electric pumps, electrostatic powder and liquid applicators, but only for the brands we distribute and represent.

Our experts have received training directly from the brands we distribute, to accurately diagnose the failure and repair the equipment in the shortest possible time.

Services for the industries

Training for industrial welding, cutting and finishing operators

We have technical personnel trained directly by the brands we represent in the correct use of welding, cutting and industrial finishing equipment. If your operators receive this training, they could avoid common mistakes in the operation and make better use of the equipment. Likewise, the equipment could have a longer useful life and would have fewer failures, since it would be used correctly.

Although it does not correspond to an AWS certification, our welding and cutting training improves safety and manages to correct operator errors in the application of processes, creating awareness of the risks they run. In this way, accidents that cause human and material damage are avoided, it teaches how to increase the durability of consumables and improves production in general.

Our industrial refinishing training teaches operators to avoid accidents, paint more efficiently, consume less paint, etc. We also teach techniques for electrostatic painting, whether powder or liquid. In addition, the training includes the proper maintenance that should be given to the painting equipment after each period of use.

A multinational company

We sell all over the world

During these more than 40 years of experience, we have continued to grow and cover new markets. We keep getting clients in one country after another.

+25,000 Customers

With over 40 years in the field, we have gained the trust of more than 25,000 clients.

+125 Countries

We have clients all over the world, distributed in more than 125 countries.

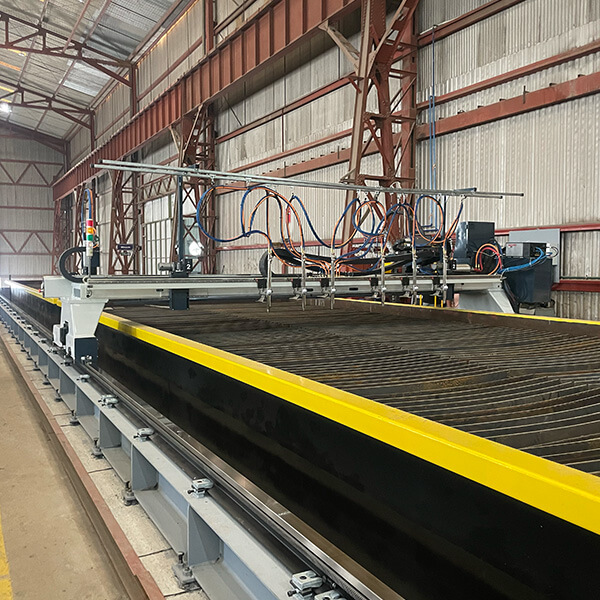

Services for the industries

Design and installation of automated welding and cutting plants

Sooner rather than later, the time will come to take the step toward mechanization and automation. This will allow the company to grow exponentially since it will be able to produce more, with better quality, and avoid accidents.

We refer to mechanization when equipment (such as a welding carriage) is programmed to direct the movement of the torch advance with the welding arc in order to carry out a specific operation, for example, a limited distance weld beam. It requires the constant intervention of an operator to initiate new operations. Although the auxiliary equipment that allows mechanized welding has a certain degree of complexity, actually the functions they can perform are simple and their programming is usually easy.

Automated welding is when a robot is programmed to perform complex welds, which may include manufacturing a whole piece in a single operation. Usually welding robots are integrated with special cells, positioners, and other equipment that allow the precise adjustment of the piece to be welded. Although the advancement of technology has made the use of robots easier, and the operations they can perform are becoming more complex every day, the intervention of operators is still necessary, especially for the placement and removal of the pieces to be welded, as well as for the addition of filler material.

We study your needs and production targets to offer you the most appropriate solution. We are not cookie cutters. Our service includes the study of the facilities, assessment of the necessary equipment, installation, training, and even the ROI calculation.

We supply the equipment, accessories, and consumables for day-to-day production. We have experience in the installation of automated welding and cutting plants since it has been our job since 1979.

Services for the industries

Design and installation of painting plants

Industrial finishing is generally the last step in production. However, its importance lies in the fact that the quality of the finish affects the appearance and durability of the product. In addition, the industrial finishing process can impact the speed of production.

To design a customized solution, we first dedicate ourselves to learning about your process. If the painting plant is in operation, we look at what equipment they have and what coating they usually apply. If a completely new area is going to be used for industrial finishing, we are interested in knowing which coating will be used and on which substrates or surfaces.

We visit factories to understand your needs and circumstances. As there are several types of coatings that can be applied (such as epoxy, two-component, catalyzed lacquers, etc.) on various types of materials (such as metal, plastic, wood, etc.), verifying in person what the company needs allows us to recommend the appropriate equipment (and even coatings) for the effective and efficient application of the finish.

Our service includes the design of the floor plan with the recirculation systems. The installation of the ideal equipment and accessories for the application of the coatings and the training so that the operators reach the greatest potential of their work.

We are the most appropriate to design and install the painting plant for your company, since the manufacturers of the leading brands in industrial finishing have instructed us to design personalized solutions for our clients. We know every part of the industrial finishing process and all the equipment and accessories that are needed.

We make sure of all the details when designing a customized industrial finishing solution for each company, taking into account the particularities of each project. Since 1979 we have been solving the demands of the industry with more than a number of successful projects that prove our expertise in the field.

Services for the industries

Update of automated cutting equipment

We can update your automated cutting systems to adapt them to your current needs, with the latest technology. We study your needs and production objectives to offer you the most appropriate solution.

Our service includes the study of the facilities, advice on the necessary equipment, installation, training, and even return on investment calculations.

We supply the equipment, the accessories, and the consumables for day-to-day production. We have a lot of experience in the installation of robotic systems, orbital welding, and high-precision cutting equipment because it has been our job since 1979.

A multinational company

We can be your supplier

Whether you are a small factory or a large surface mine, we have the capacity to meet your needs. We give a great service to everyone equally.

+8 MM US Dollars

Available inventory for immediate sale of products and spare parts.

+200 Employees

We have a combined workforce of over 200 employees.

Let's talk business

How can we help you?

Leave us your information here and in record time we will be contacting you.