Technological solutions

Solutions for the Energy Industry

The energy industry is what moves civilization. The objective of the energy industry is to produce and supply this power to companies and people.

When we talk about the energy industry, it can be about the extraction of oil (fossil fuels) or the production of renewable energy, which is more in demand nowadays.

Equipment, Spare Parts, Accessories and Consumables for Welding, Cutting and more.

In our modern world, energy is essential for transportation, agriculture, communications, and other aspects of daily life.

Access to power has helped companies to produce more and better. Likewise, power has allowed people to have a fuller and healthier life. Hence the importance of the energy industry.

The energy industry is one of the most related to welding and cutting. Welding and cutting operations are required daily in practically each of the production stages. Basically, we can divide the energy industry into

- The oil industry

- The electric power industry

- The nuclear power industry

- The renewable energy industry

Let’s see some details of each of them.

The sources of energy

Energy sources can be divided into primary and secondary.

Primary sources are those that are found or can be exploited naturally. They can include oil, natural gas, coal, solar, hydrological, geothermal, nuclear, and wind energy.

Secondary sources are those that can be obtained through one of the primary sources. Electricity is a widely used secondary energy source around the world.

Solutions for Industries

The oil industry

Most of the energy consumed in the world is obtained through the oil industry. The oil industry is joined by the petrochemical industry, which creates useful products and raw materials from oil and natural gas.

The oil industry is responsible for exploring, extracting, refining, transporting, and distributing oil and oil-based products. Viewed as a whole, oil is still the largest and most powerful industry in the world, in terms of its capital. Fossil fuels (oil and coal) cover approximately 59% of the world’s energy needs.

Thanks to the oil industry, many components are obtained for the pharmaceutical industry, manufacturing of plastic products, solvents, chemical substances, and more.

Around the world, on average, about 30 million barrels of oil are consumed per year. To produce these, the oil industry requires a lot of welding and cutting equipment, accessories, and consumables.

Solutions for Industries

The electric power industry

The electric power industry is responsible for producing electricity from primary sources of energy, in order to store and distribute it.

Electrical energy can be obtained through hydroelectric plants, nuclear, etc. Since it is a secondary energy source, its consumption is not calculated in the same way as it is done with fossil fuels, but it is widely used in most countries.

It is convenient to convert energy to electricity in order to conserve and transport it. This makes the electric power industry very important worldwide.

Solutions for Industries

The nuclear power industry

The nuclear power industry produces electricity and other forms of fuel through nuclear fission, mainly from uranium and plutonium.

Nuclear power meets approximately 5% of the world’s energy needs.

Although nuclear power plants are present in several countries, with France being the country with the most nuclear facilities, the installation of new reactors is still cautiously considered, particularly in countries with geological fault lines or prone to political instability.

Solutions for Industries

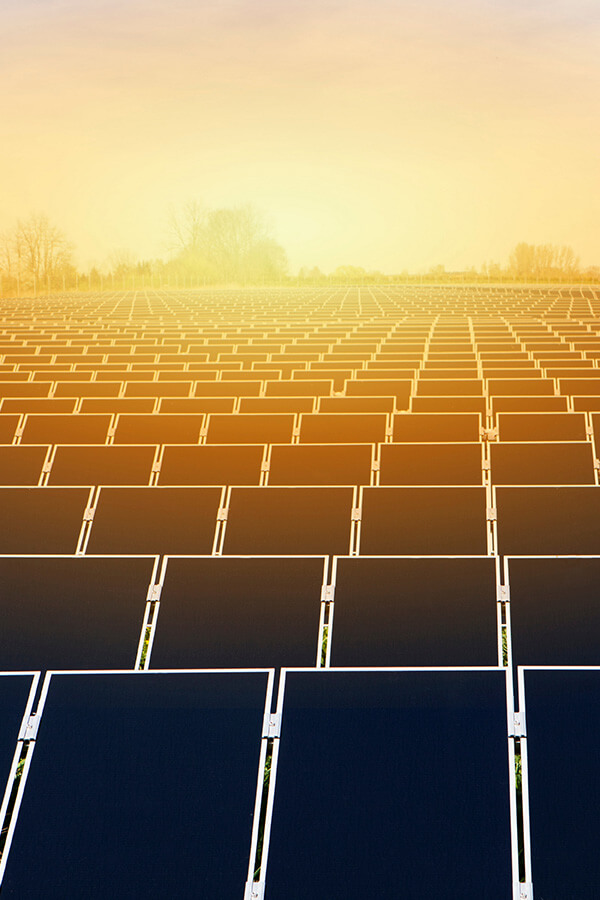

The renewable energy industry

The renewable energy industry is responsible for producing and distributing all types of energy that are considered alternative and self-sustaining. Among these, we have solar energy, hydroelectric, and wind.

Since fossil energy has been the most important for many decades, these other sources of energy are called alternatives. However, every day more voices are coming together to support the renewable energy industry. The renewable energy industry is growing by leaps and bounds.

The use of solar energy, as an example, is growing by 20% each year, making it the fastest-growing type of energy worldwide.

Technological solutions

We are close to you

We have offices in various countries in the Americas, and we sell to more than 25,000 customers in some 125 countries around the world.

Codinter

United States

(+1) 305-470-4513

Codinter

Colombia

(+57) 2-335-1214

Codinter

Brazil

(+55) 11-4815-1735

Codinter

Mexico

(+52) 55-4170-8207

Codinter

Venezuela

(+58) 424-414-1923

Equipment for Industries

Equipment for the energy industry

So far we have considered various sections of the energy industry, such as the oil, electric, nuclear, and renewable industries, focusing on what makes them different.

However, the equipment and machinery they use may be similar. Therefore, now let’s see what are some of these groups of machines necessary for the energy industry.

Engine-driven welders

In most places where oil extraction and refining activities are carried out, there are large carbon steel pipes. The same can be said regarding other plants where energy is produced or stored. These pipes must be maintained and repaired over time so that the operation is reliable.

In order to carry out these heavy jobs, generally in extreme environments, for long hours, companies mainly use engine-driven welders.

These have clear advantages: maintenance is minimal, service life is long, the operation is simple, and performance is high. In cases where welding in the open field is required, engine-driven welders are the only viable option, since they do not require a connection to electrical power to function.

Multiprocess welders

In some operations, various welding processes may be required, depending on the specific work to be performed. These welding processes mainly are MIG, TIG, or Stick. To deal with this situation, it is more convenient to have multiprocess welding equipment, which due to its versatility can be used on almost any occasion.

New inverter technology has also been helpful. These multiprocess welding equipment can be smaller but more powerful. This achieves greater portability and reduces wear on the operator. In addition, some technologies like Miller’s ArcReach help operators operate some functions remotely, saving time and preventing accidents.

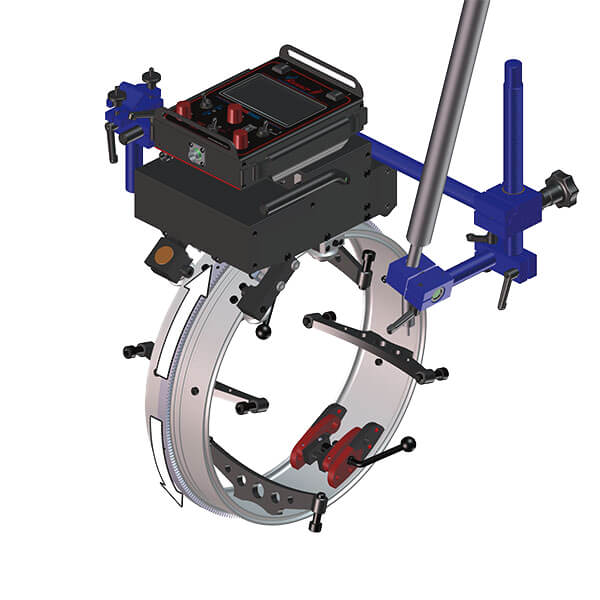

Orbital and Pipe Welding

One thing is to extract the oil and another thing is to transport it. The same goes for natural gas. For that, large pipes are necessary for long distances. Primary energy transportation is an industry unto itself.

To weld pipelines, mechanized or semi-automated orbital welding equipment is required. There are several options on the market that mainly vary in size and capacity.

The principle of how they work is basically the same: The electrode is rotated around the pipe in an orbit by means of a track or some tweezers. An operator is in charge of setting up the cutting or welding and from then on the equipment executes the operation.

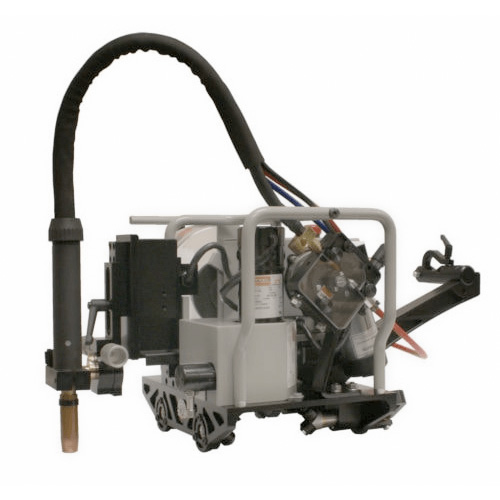

Cutting

Cutting equipment is needed wherever something is in the works. In the energy industry repairs are being done everywhere, and a portable cutting equipment, like the Hypertherm Powermax45 is ideal to get the job done. In some cases, the operations might require more power, and the Powermax105 SYNC can be the effective solution needed.

Even more, in some bigger plants the maintenance requires the use of a mechanized plasma cutting solution, like the Hypertherm MAXPRO200, in place, due to the high volume of quality cutting required or the thickness of the metals in use.

We have solutions, not problems

Solutions for Industries

Our technical advisors have decades helping industries to produce in a safer, more efficient and profitable way. We don’t just sell products, we offer solutions that improve processes.

The mining industry is responsible for the extraction, transport, and processing of solid mineral elements that can be found…

The metalworking industry usually helps other industries and plays a prominent role as a basic link in the production…

The construction industry is probably the one that most directly affects people’s lives…

Let's talk business

How can we help you?

Leave us your information here and in record time we will be contacting you.