Spray guns are the central element in industrial finishing tasks. In this article, we will answer key questions from those who work in the industry.

What are spray guns

Spray guns are equipment that can spray paint or varnish using air pressure to apply it or spread it on a surface.

These guns can be used to paint on any type of surface or substrate, be it metal, wood, stone, clay (ceramics), and porcelain, plastic, glass, and textile.

For this reason, spray guns are fundamental tools for any type of manufacturing industry and repainting services, since they allow industrial finishing of any of their products economically and efficiently.

Spray guns were invented in 1888 by Dr. Allen DeVilbiss in the United States. Then, his son continued to improve the invention, producing the first spray gun to use compressed air.

The development of spray guns technology has continued to this day.

For the vast majority of industrial finishing jobs, it is essential to use spray guns. Simply, it is the option that is the best in price and production speed.

Spray guns can be classified according to several criteria. For example, they can be grouped according to:

- The feeding of the paint

- The atomization technology they use

- The way of use

But in this article, we will categorize spray guns according to the pressure they use or the paint transfer mode.

How a spray gun works

In just a few words, the spray of coating happens when the paint is applied to an object (the surface to be painted) through the compressed air gun.

When the trigger is pressed, the paint mixes (although in some systems it does not mix) with the compressed air stream and is released in a fine spray.

The consistency and pattern of paint can be defined and regulated by the correct use of the cup or tank where the paint is placed, and the nozzle that is chosen.

Regardless of the type of technology used to paint, it is extremely important to frequently disassemble the nozzle of the spray gun to clean it and prevent it from becoming clogged with traces of dry paint.

Advantages of spray guns

- Allow the paint to be applied uniformly on the surface

- Allows different types of surface (even irregular or rough) to be painted efficiently

- Save time and production costs

- Can be configured for automated use

- There is good diversification for specific applications

- There are different ways to configure each gun according to the need for finishing

YOU CAN BE INTERESTED IN: Paint Pumps: types and uses in industrial finishing

Parts of a spray gun

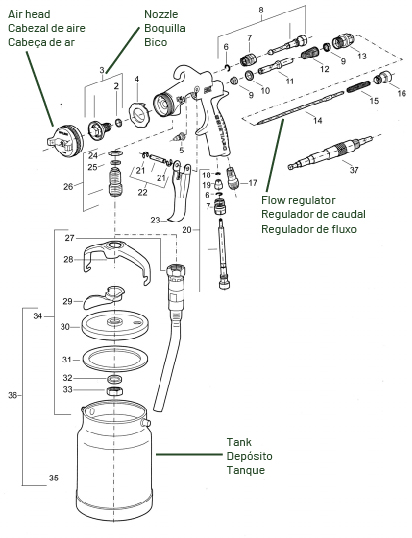

The spray guns are divided into these basic parts:

- Airhead

- Flow regulator

- Nozzle or peak

- Tank (depending on its type the gun can have a deposit or be connected to a tank)

Airhead

The airhead is, perhaps, the most important part of the spray gun.

This part of the gun directly affects the quality of the result and the amount of paint used.

Depending on the type of gun, the mixture of air and paint can happen internally or externally.

Flow regulator

It is the piece that determined how much paint will come out through the nozzle and even allows to vary the shape of the paint jet.

It is usually located in the handle or trigger.

The very tight restriction of the flow regulator is not good practice.

It has happened that the operators close the flow regulator a lot and with the force of the hand, exert a very large pressure on the trigger, which is transferred to the flow regulator, opening when the trigger is pulled.

This force deforms the flow regulator and generates drips.

It is better to adjust the flow from an external source such as the fluid regulator or restrictor and not the gun.

In this way, the flow regulator will be only activating and deactivating the painting flow.

The nozzle

It is where the paint is expelled. Many spray guns come equipped with several interchangeable nozzles, so the operator can choose the one that is appropriate according to the case.

Some brands of spray guns, such as Binks and DeVilbiss, even have extensions to get hard-to-reach places.

Although there are more than 15 types of nozzles available in the market, the 3 most used in industrial finishing processes are those of these spray technologies:

- Low Pressure Aspersion

- Airless

- Airless Air Assisted

What are Airless spray guns?

Airless is a system that allows the spraying of paint and other coatings at high pressure. Although compressed air is used to force paint out, the air is not mixed with the paint or coating at any time during the process.

In Airless systems, the pressure of the piston pump is used, which compresses the paint when passing through a very small craft. This in turn passes through another hole of longitudinal or oblique shape that gives the flat finishing pattern.

In this way, the over-spray of the coating is avoided, which usually forms clouds of paint.

This system is ideal for applying high viscosity paints, such as plastic paints, since these generally need more power to be applied.

These Airless spray guns can be integrated when the air compressor is in the same gun or operating with an external compressor. Airless piston or diaphragm paint pumps can be used and operated electrically, pneumatically, or gasoline

They are ideal for painting large surfaces in a short time because they cover more in each application and save paint.

The Airless Air Assisted technology is the same as Airless, but in this case, the air is used to flatten or soften the paint pattern generated by the pump by passing it through a very small nozzle.

In these systems, it is very important to correctly adjust the pressure of the pump relative to the nozzle of the gun. If the pressure is missing or leftover, the paint pattern may be left with lips up and down or loaded at the corners.

Types of spray guns

There are many ways to classify spray guns. They could be classified by the paint supply, by the technology they use, by the way of operation, etc.

However, a practical and simple way to classify the spray guns would be by the pressure they use and the way the paint is transferred.

Spray guns according to pressure

- High-pressure manuals

- Low-pressure manuals

- High-pressure automatic

- Low-pressure automatic

Spray guns according to the paint transfer mode

- Airless

- Airless Assisted

- Conventional

- HVLP

- Electrostatic

The latter, spray guns with electrostatic technology have become so important that we separate them into another category and dedicate a whole section to explain their operation.

Even more, low-pressure manual guns can be subdivided into the following categories:

- Fed by suction

- Fed by gravity

- Fed by pressure

Automatic low pressure guns do have not such categories, as they are all fed by pressure.

However, manual and automatic high pressure guns can be divided into airless and airless air-assisted.

What are HVLP spray guns?

HVLP stands for High Volume Low Pressure. These guns use a high volume of air to spray the paint, which for the most part goes to the surface to be painted, achieving a reduction of up to 75% of the paint loss.

In addition, as less paint is dispersed in the air (the rebound effect is reduced), it could be said this system is healthier or more environmentally friendly.

Some models of HVLP guns also bring hot air, that way helping to dry the paint on surfaces and to disperse more quickly the cloud of paint formed.

However, they are ideal for specific work or detail because the paint cloud formed by the reduction of overspray prevents covering large surfaces in a short time.

Spray guns bestsellers

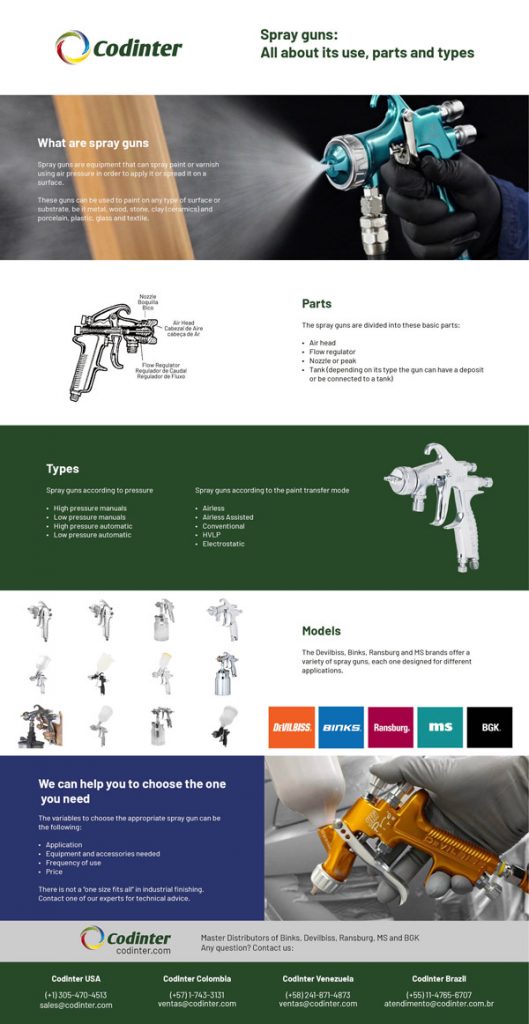

The DeVilbiss, Binks, Ransburg, and MS brands offer a variety of spray guns, each one designed for different applications.

Some of the most wanted models in the market are the following:

Of course, choosing a spray gun does not only depend on how sold is it. It is also needed to know if is it appropriate for what is going to be used. Ask for our specialized advice before making your investment.

What is viscosity?

The viscosity of a liquid is a measure of its internal resistance to flow or, simply put, its thickness. The type of liquid and its temperature determine the viscosity it has at any given time. Therefore, when measuring the viscosity, the temperature should be indicated.

The measurement of the viscosity of a liquid is expressed in poise and centipoise (1 poise = 100 centipoises). The flow rate, measured in seconds from a Zahn, Ford, or Fisher bucket, is very used data to know the viscosity of the coating.

It is very important to control the viscosity of the materials to applying them efficiently and with quality on the surfaces to be painted.

How to choose the appropriate spray gun

When we are asked about which is the spray gun you would need for your personal use or your company, there is no single answer. The variables to choose the appropriate spray gun can be the following:

- Application

- Equipment and accessories needed

- Frequency of use

- Price

Application

The objective or application that the spray gun will have is the most important factor in choosing the appropriate one.

Among others, you should ask yourself the following questions:

- What kind of paint or varnish will you use?

- Will it be used to paint outdoors or inside a paint booth?

- Will it be used by operators or is it planned to make an automated system?

- Will many small surfaces or few large surfaces be painted?

- On what surfaces will the paint or varnish be applied?

Equipment and accessories needed

To perform industrial finishing work, the spray gun is not the only necessary. Depending on the application, in some cases, some other equipment and accessories may be needed such as:

- Filters

- Tanks

- Hoses

- Regulators

- Compressor

- Cups

- Bombs

YOU CAN BE INTERESTED IN: Electrostatic atomization: What is it and what equipment is needed

Frequency of use

Although all spray guns of the brands DeVilbiss, Binks, Ransburg, and MS are excellent, they have been created with different capacities.

The design of a gun that will be used for many hours daily varies from the one that will be used for shorter periods.

In particular, the capacity of the paint tank is an important issue to be defined in this regard.

Price

In industrial finishing applications, this should not be the dominant factor, but one more factor to take into account for the decision.

The good purchases of equipment, accessories, and industrial finishing consumables are made by obtaining exactly the product that is needed or that is ideal for its use, buying it at the best market price.

On many occasions, a spray gun, or even a piece of complete equipment with included accessories can be a costly investment, but in the long run, it will result in the most profitable because it will save time and materials.

In this particular case, Codinter can offer all spray guns and industrial finishing products in general at the best market price.

We focus more on what will be best for your company in the short, medium, and long term.

In a nutshell

Although there are many brands of spray guns, those of the Binks and Devilbiss brands have proven to be the best in price and value.

To properly choose a spray gun, it is necessary to define what its use will be and on what surfaces it will be used.

There are several spray gun technologies. A good idea would be to talk to an expert to determine which is best suited to your industrial finishing needs. You can count on the Codinter experts to make your decision.

We regularly publish useful information for the industrial finishing industry. Subscribe here to our monthly newsletter to stay informed.

As a summary, we have done this infographic where you can easily see what is explained in this article.

Did you like this article? We invite you to comment. Do you have questions? Contact us or make them in the comments section and very soon we will be answering.

This Post Has 4 Comments

Hi,

The paint sprays you mention, Which paint sprayers better for me?

With which I can paint my house, furniture and other myself? It would be great for me if you could tell me a little bit Please?

And How long will it last, is there any guarantee or warranty available?

I am very impress from your blog and thanks for the sharing information, keep it up

I am waiting for the next strong spray and Your website is very beautiful. I like it, thank you.

Great blog thanks for sharing this..