A light-duty plasma cutting machine can become a need for any workshop, artist, contractor, etc. that so far have been using oxy-fuel and is ready to make the leap to a better solution.

Actually, after experiencing a handheld plasma machine, almost nobody wants to return to oxy-fuel.

That is because even a light-duty plasma cutting system can make a big difference in efficiency and productivity.

So, in this post, we are going to consider what a light-duty plasma cutting system is and which one you should get.

But before getting into this amazing topic, let’s consider what plasma cutting is.

What is plasma cutting?

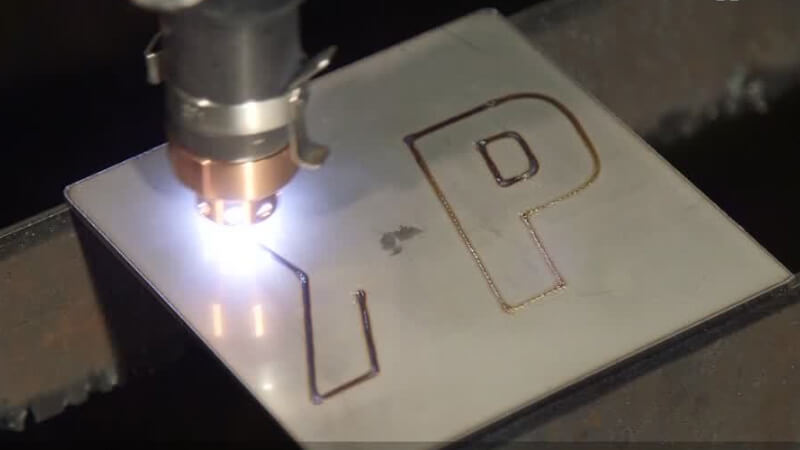

Plasma cutting is an electrical process that cuts conductive materials by means of a compressed and ionized air or gas expanded and accelerated by electricity.

The electricity heats the gas with a temperature above 20,000 °C up to the point of converting it into plasma, the fourth stage of the matter.

When the gas gets in contact with the electrode, in the tip of the torch, it is ionized and more pressure is created.

So now, this ionized and compressed air or gas is able to cut through different conductive materials like aluminum, stainless steel, titanium, copper, brass and more. This gas can be nitrogen, other gas or a gas mix, in case of very specific applications.

These gases are fed into the machine by a compressor. Each machine indicates how many PSI of compressed air or gas are needed for standard operation.

Usually, the jet of plasma is directed by a torch. Each torch can be suitable for some types of materials or processes.

Torches include water or air cooled gas nozzles which constrict the arc causing the narrow, high-temperature, high-velocity plasma jet to form.

The air that goes through the torch can be handled to create a harder or softer jet of plasma by accelerating or breaking up the stream of gas.

This way the beam of plasma can penetrate in different material thicknesses and be maneuvered according to the will of the operator.

What can be considered light duty?

Most people classify plasma cutting systems in light, medium and heavy-duty. A handheld plasma cutting machine used in a small cutting table can be considered light-duty.

In general terms, a medium-size cutting table powered by some plasma cutting machine would be a medium-duty system.

A mechanized cutting system, which could occupy the heavy-duty slot, can be built in a stronger structure and composed by more than one cutting machine.

But that classification is not a general rule for plasma cutting manufacturers.

For the sake of this post, as quoted before, we are considering a handheld or portable plasma cutting machine as a light-duty one.

Now, before buying a light-duty plasma system, you may need to know when to use a portable and when to use an automated system. So, let’s consider some of it.

When to use handheld plasma cutting machines?

Basically, there are three reasons for using only a handheld plasma system, which are:

- The job requires mobility

- The job is one-time cut

- The piece to be cut is small and is easier to cut it by hand

In some field operations, like when building a pipeline, some cuts should be done in the very place. In those cases, a portable cutting plasma machine is a must.

Actually, many mechanical contractors opt for a lightweight plasma cutter that permits mobility.

Even in big workshops, sometimes a small cut is required, maybe to finish a structure. It would be easy to use a handheld cutting plasma machine for those cases.

What about oxy-fuel cutting?

The oxyfuel cutting process has been used for decades for welding and cutting.

Before a reliable source of electrical power was commonly available for industries, that process was the means for almost all companies.

But nowadays, modern welding and cutting processes, used by powerful machinery have taken place in the whole industry.

Therefore, oxyfuel is mainly used for applications where plasma cannot reach the needed cutting capacity. In a future article, we will explain this topic better.

If you need oxyfuel equipment, visit the International Gas Equipment website.

When to use automated plasma cutting machines?

When cutting becomes a regular activity in any workshop, maybe to carry on a certain operation, the time for getting an automated plasma cutting machine has arrived.

For most first-timers, it is going to be a medium-duty plasma table, powered by a cutting machine.

But in any case, it is extremely important that you answer the following questions, which can indicate to you what automated plasma cutting system you should get.

- What thickness of metal will you cut on a daily basis?

- What is the maximum thickness you might cut?

- How fast do you want to cut?

- What cut quality do you require?

The power of a plasma cutting machine is determined by its amperage and voltage capacities.

The plasma cutting process usually requires relatively high voltage and low amperage levels, just the opposite of welding machines.

So, as can be confusing, it is a piece of good advice to ask an expert before purchasing any cutting equipment. We are always ready to help you out on this topic.

Equipment, Accessories, and Consumables for light plasma cutting

Among other equipment, for a light-duty cutting system to work properly, a cutting table, a power source, and a CNC are required. Let’s review some of these needed parts.

Regarding the cutting table, we have options for you. For systems of this type, we have successfully installed the ProArc Magicut and the Extreme Practicut. These are available in several sizes that can be adapted to your own needs.

We have several options about the CNC. In most cases, this depends on your very needs. So, we prefer to understand better your production needs to find the right CNC for you.

The plasma cutting power unit

Among the most used systems for light-duty plasma cutting, we can find some Hypertherm equipment like models Powermax30 XP and Powermax45 XP.

Powermax30 XP plasma system

This is a handheld plasma cutting machine capable of a wide array of applications. It is so versatile that it can cut thick material and also carry out detailed cutting in thin metal sheets.

Some of the metals that can be cut with the Powermax30 XP plasma system are aluminum, stainless steel, and mild steel. It can use air or nitrogen.

Powermax45 XP plasma system

This is another handheld plasma cutting equipment with remarkable capacities. It can separate metal up to 29 mm (1 – 1/8 ”). However, its quality cut quality is between 16 mm (5/8 “) to a maximum of 22 mm (7/8”).

Note that if this machine is used on a CNC system, the Powermax 45XP has a maximum drilling capacity of 12 mm (1/2 “).

One of the advantages of this machine is an automatic gas adjustment for a quick, simple setup and operation.

Gouging with precision, marking and spot weld removal are some capabilities of this system.

Both handheld and mechanized torches can be used, for a wider range of metal thicknesses to be cut.

Of course, each one of them has accessories and consumables required for its work. We can supply all of those at the right time and at an unbeatable price.

We want and can help you define what light cutting equipment is right for your operation. Contact us at any time to receive more information.