There are certain advantages and disadvantages in the comparison between plasma cutting and oxyfuel. Let’s start with the slag.

The slag

The slag is the metal that melts and remains on the edge of the thickness of the metal by detachment. In the case of plasma cutting the slag is easy to remove, even with a small blow it could come out.

In the oxyfuel the slag is quite difficult to remove once the cut is finished since it is very attached to the sheet and it is possible that a tool must be used to detach it.

Obviously the slag has a lot to do with the cutting speed, for both cases.

The cutting speed

In oxyfuel the process is much slower than in plasma cutting. Even in thin thicknesses, plasma cutting can reach cutting ten times faster than oxyfuel. Even more, in oxyfuel process a preheating must be done before starting cutting.

In plasma cutting, once the equipment is turned on, you can start cutting. The speed is justified in particular in high thicknesses in oxyfuel since for both processes, as the thickness increases, the cutting speed decreases.

The speed also has to do with the affected thermal zone. The lower the speed, the greater the heat that is added to the piece.

That can generate deformity in the piece, even more when they are thin sheets, of a range between 6 millimeters to 1.5 inches.

Sheets less than 6 millimeters thick can also be cut, but in oxyfuel the finish and the quality of the process is not the most suitable for production, compared to plasma cutting.

The deformations

The deformations are produced by heat. In the case of plasma cutting the deformity of plasma cutting is very low compared to oxyfuel since much more heat is applied to the latter.

The thinnest sheets are the ones that tend to deform more by heat.

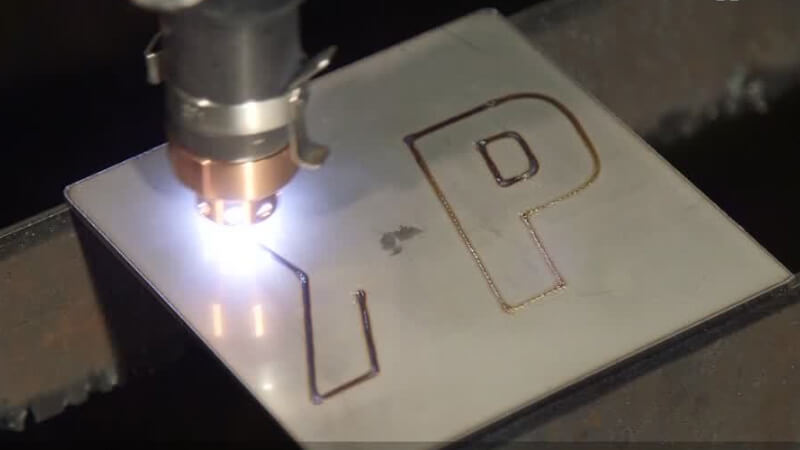

The cutting quality

The quality of the cut is also varies in the comparison between plasma cutting and oxyfuel . As for large thicknesses, greater than 1.5 inches, the cut quality is very similar in both cases.

It is even recommended to use oxyfuel in manual equipment when making cuts in sheets of thickness greater than 1.5 inches because the cutting speeds are equalized but it is much cheaper.

As for thicknesses, there is currently plasma cutting technology that allows cutting up to 8 inches thick, but is limited to mechanized systems only.

Manual plasma cutting is not possible until now for thicknesses greater than 1.5 inches. In the case of oxyfuel the recommended limit is 6 inches.

Speaking again of the slag, in the case of plasma cutting, once the cut is finished, it is practically a finished product. In the case of oxyfuel , depending on the thickness of the sheet, it will be easier or more difficult to remove it.

Finally, an advantage that oxyfuel has over plasma cutting is the initial investment. In oxyfuel the investment is low since what is needed is a torch, two gas cylinders and regulators.

In the case of plasma cutting, if you are willing to do manual cutting, there is an average investment to make, since you need a plasma source and torches.

As a positive aspect, in plasma cutting the gas used is air, so costs are saved.

We can help you to set up your plasma cutting equipment

We distribute Hypertherm plasma cutting equipment to some markets. Powermax equipment has proven to be reliable and durable. Download here this brochure about why to choose Hypertherm’s Powermax line.

Download this PDF brochure about the advantages of plasma cutting over oxyfuel.

Download this infographic in PDF about the advantages of plasma cutting over oxyfuel.

Conclusions of the comparison between plasma cutting and oxyfuel

Depending on the specific work to be done, one process will be more advisable than the other. Everything would depend mainly on the thickness and the other parameters mentioned above.