Annular cutters and drill bits are both tools used to create holes in materials, but they have different advantages and disadvantages.

In this article we will compare annular cutters and drill bits regarding speed, quality, and durability. This way you can take an informed decision when defining what equipment to use for your hole making needs.

What are annular cutters?

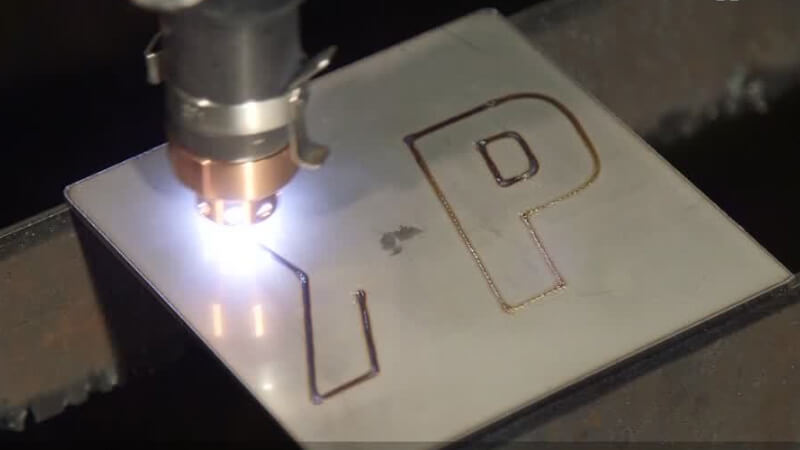

Annular cutters are hollow tubes with sharp cutting edges on the outside that are used to cut holes. They are also known as ring cutters or annular end mills.

They are typically used to create large holes (over 1/2 inch in diameter) in metal and other hard materials. As the cutter rotates, the teeth cut a ring of metal from the material being drilled. The annular cutter then removes the ring of metal, leaving a clean, finished hole, with minimal burring.

Annular cutters are available in a variety of sizes and diameters. The size of the annular cutter you need will depend on the size of the hole you need to drill. Annular cutters can be used with a variety of drills, including magnetic drills, drill presses and portable drill presses.

Most annular cutters are typically made of high-speed steel (HSS) or carbide. HSS annular cutters are less expensive than carbide annular cutters, but they are not as durable. Carbide annular cutters are more expensive, but they last longer and can be used to drill holes in harder materials.

Features of annular cutters

The features that most identify annular cutters are the following:

Ring shape: Annular cutters have a hollow, ring-shaped body with saw-like teeth on the bottom edge. The center is open to allow material removal.

Carbide teeth: The cutting tips are made of tough carbide to handle high speeds and pressures. Teeth are brazed or friction-fit to the cutter body.

Pilot pin: A center pilot pin helps stabilize and guide the cutter during cutting. It fits through the open center of the ring.

Material removal: As the cutter spins at high RPMs, the teeth cut a narrow ring into the material. The center disc removes through the open center.

Clean cuts: Annular cutters produce smooth, burr-free holes with minimal need for secondary finishing.

Size range: Available in diameters from less than 1 inch to over 12 inches. Maximum depth of cuts around 2 inches.

Coolant: Require copious amounts of cutting fluid to cool and lubricate the cut. Compatible with water or oil-based coolants.

Applications: They are used for precise, repeatable holes in sheet metal, pipe, plastics, composites and other structural materials. For some applications, only annular cutters can be used, no drill bits.

Advantages of annular cutters

Annular cutters offer a number of advantages over other types of drill bits. Here are some of these advantages:

Speed: They are faster than other types of drill bits, such as twist drills and step drills.

Efficiency: They are more efficient than other types of drill bits, as they only remove the material that is necessary to create the hole.

Precision: Annular cutters produce cleaner, more finished holes than other types of drill bits.

Power: They require less power to operate than other types of drill bits, which can extend the life of your magnetic drill or drill press.

Disadvantages of annular cutters

Nothing in this world is perfect, and annular cutters don’t escape that reality. Here are a couple of disadvantages:

Depth: They are limited to about 2″ depth of cut, while drill bits can make much deeper holes when run at conservative speeds.

Price: They are more expensive than drill bits, and they require a special drill press or magnetic drill to use.

Main applications of annular cutters

Annular cutters are a versatile tool that can be used for a variety of applications. They are typically used in industrial and commercial settings, but they can also be used by DIYers for home projects. Here are some of the applications where annular cutters are mainly used:

Construction: They are used in construction to drill holes for electrical and plumbing conduits, as well as for structural steel and other metal components. Magnetic drills are commonly used in the construction industry, because they are portable and can work even overhead.

Manufacturing: They are used in manufacturing to drill holes efficiently in a variety of metal products, such as automotive parts, aerospace components, and electronic devices.

Maintenance and repair: They are used in maintenance and repair to drill holes in metal equipment and machinery.

DIY projects: Even though they are mainly industrial, annular cutters can be used by DIYers for a variety of projects, such as installing home security systems, building custom furniture, and repairing metal fences and gates.

What are drill bits?

Drill bits are specialized tools that are designed for heavy-duty use in industrial and commercial settings. They are typically made of durable materials, such as high-speed steel (HSS) or carbide, and they are designed to withstand the rigors of repetitive use.

Industrial drill bits are available in a variety of sizes and types, and they can be used to drill holes in a variety of materials, including metal, wood, concrete, and masonry.

Types of drill bits

Here are some common types of industrial drill bits used for heavy-duty drilling applications:

Twist/Masonry Bits: Used with rotary hammer drills for drilling in concrete and masonry. Made from tungsten carbide.

Auger Bits: Deep spiral flutes move material up and out of deep holes in wood or soil. Used for post holes and foundations.

Hole Saws: Cylindrical saws with cutting teeth to make large diameter holes in wood, metal, drywall. Center drill bit guides the cut.

Spade Bits: Bore large diameter holes in thick wood quickly. Two spurs guide the narrow cutting blade.

Unibits: Step drill bits with conical shape to drill a range of hole sizes with one bit. They are ideal for sheet metals.

Indexable Insert Bits: Industrial bits with removable carbide inserts as the cutting tips to allow replacing when worn. For high wear applications.

Core Bits: Hollow tube bits with industrial diamond grit on the cutting face. Used for concrete and geological core sampling.

Counterbores: Enlarges and creates a shoulder at the top of an existing pilot hole. For socket head cap screws and precision holes.

Counterinks: Conical shaped to create a beveled recess for a countersunk fastener head.

How to choose an industrial drill bit

As you can see, there is a wide variety of industrial drill bits. So, when choosing industrial drill bits, it is important to consider the following factors:

The type of material you will be drilling: They are available in a variety of materials, each designed for a specific type of material. For example, carbide drill bits are best for drilling holes in hard materials, while HSS drill bits are best for drilling holes in softer materials.

The size of the hole you need to drill: They are available in a variety of sizes. Choose the size drill bit that matches the diameter of the hole you need to drill.

The type of drill press you will be using: They are designed to be used with a variety of drill presses or magnetic drills. Make sure that the drill bit you choose is compatible with the drill you own.

Annular cutters vs Drill bits: Speed

Annular cutters are generally faster than industrial drill bits, such as twist drills and step drills. This is because annular cutters produce continuous round cuts, only removing the material that is necessary to create the hole, while twist drills and step drills cut via shearing action, requiring lower speeds, and removing additional material.

Cutting speeds of 100+ SFM are common for annular cutters, while twist drill bits are limited to lower speeds, typically 30-50 SFM for smaller bits and under 25 SFM for bits over 1/2″ diameter. Higher speeds cause premature wear.

This is important because, if you have a project in which you need to cut several holes, and you have calculated that using drill bits that task can take up to 10 days, by using annular cutters you could do the same in 3 days. Faster production means cost savings and satisfied customers.

Annular cutters vs Drill bits: Quality

Annular cutters can produce cleaner, more finished holes than industrial drill bits. This is because they cut a ring of metal from the material being drilled, while twist drills and step drills can leave behind burrs and other imperfections, which can be a problem in some applications.

Also, less heat is generated due to faster annular cutters speeds, improving hole quality. Proper use of cutting fluid is even more critical for drill bits to counteract heat at the cutting edges.

Annular cutters produce very precise, clean holes with excellent perpendicularity to the workpiece. The guiding pilot pin improves accuracy. In contrast, standard twist drill bits are prone to wandering and producing oversized or uneven holes, especially in deep holes when the bit can flex.

As time goes by, and they are used, drill bits will show progressive wear, affecting precision. Bits may need sharpening or replacement to maintain size. In turn, the carbide teeth of annular cutters resist wear even across hundreds of holes. This maintains accuracy.

Annular cutters vs Drill bits: Durability

Annular cutters are generally more durable than industrial drill bits. This is because annular cutters are made of thicker materials and have a heavier-duty construction. They are also designed to withstand the rigors of repetitive use.

Industrial drill bits are also durable, but not as much as annular cutters. Industrial drill bits are typically made of thinner materials and have a lighter-duty construction. This makes them more susceptible to wear and tear.

The annular cutter’s distributed cutting edge and ring shape allow taking a bigger bite at higher feeds without overwhelming any one tooth. Drill bits concentrate the cutting forces on the small chisel and cutting edges at the drill point. High speeds can break the bit.

The cutting tips of annular cutters are made of brazed carbide resist abrasive wear from high cutting speeds. They are very durable tools capable of hundreds of holes before needing sharpening or replacement.

Regarding power, annular cutters are also more efficient than industrial drill bits, as they do not require as much to operate. This can help to extend the life of your drill press or magnetic drill.

Tips for extending the life of annular cutters

There are a few things you can do to extend the life of your annular cutters and get the most out of your investment:

Use the right cutter for the job: Make sure you are using the correct type and size of cutter for the material you are drilling and the size of the hole you need to drill.

Use the right lubricant: Use a lubricant that is appropriate for the material you are drilling. This will help to reduce friction and heat, which will extend the life of your cutter.

Keep your cutters clean: Clean your annular cutters after each use to remove any dirt or debris. This will help to prevent corrosion and wear and tear.

Store your cutters properly: Store your cutters in a dry place when they are not in use. This will help to prevent corrosion and rust.

Last thoughts regarding annular cutters and drill bits

We hope this article will help you to see more clearly the differences between annular cutters and drill bits, when it comes to hole making on an industrial scale.

We have several decades of helping companies to find the right equipment for their production needs. Feel free to contact us at your earliest convenience to help you to get your magnetic drills and annular cutters.