Choosing the right sandblasting media is, arguably, one of the most important decisions to make when any surface should be blasted.

Many production plants have one or some sandblasting equipment to use, and just the media should be changed, according to the surface and finishing required. Every surface and finishing desired may require a different media, for optimal results.

Even more, new materials and types of sandblasting media are available from time to time. As an example, despite the process is known as sandblasting, sand is not used anymore, due to the risk of silicosis. So, to make the best decision, let’s start by understanding the basics.

What is the media in sandblasting?

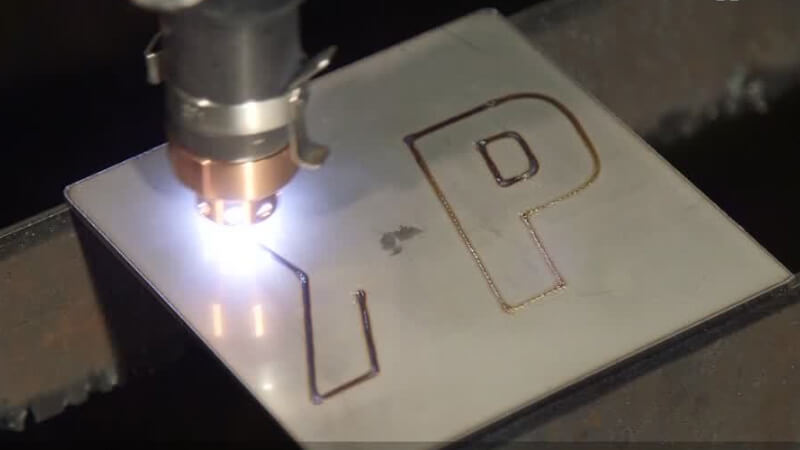

Simply put, sandblasting media is any abrasive that cleans, prepares, or finishes a surface. This blasting is a controlled eroding of the surface. This media is beamed through a piece of sandblasting equipment.

The surface to be blasted and the desired finishing are the key points to define what sandblasting media should be used. Other parameters that play a key role in choosing the right sandblasting media are available processing time and production output.

Obviously, the surface to be blasted, the sandblasting media chosen, and the required finish will define the right equipment to use and how many PSI the air compressor should provide.

Five materials sandblasting media is made of

All the types of sandblasting media are made of five basic materials, which are: organic, metal, silicate, plastic, and stone. Let’s review each one of them.

Organic

This is the media made of materials present in nature. Among these are walnut shells, corn cobs, etc. Since they are softer than other common materials are useful for more delicate applications like polishing or cleaning. They leave surfaces largely unscathed. A big advantage of this media, besides being part of nature and non-toxic, is that is reusable, due to its resistance to breakdown.

Silicate

Historically, silicate sand has been part of sandblasting, but lately is used less and less. Actually, its use is forbidden in the US and in Europe, due to the risk of silicosis. Any media that contains more than 1% de silica can cause health-related issues for the operator and all the people around.

Metal

Among all the sandblasting media available are aluminum oxide, steel shots, and grits, and more. Glass beads, black beauty, and copper slag are also to be included in this list. Usually, metal abrasives are angular and used for heavy-duty sandblasting jobs.

Plastic

There are many plastic abrasives that come from different compounds like polycarbonate and polystyrene. Since its composition can be molded, they hugely vary regarding hardness, size, density, etc. Plastic media is regularly less dense than metal and the resultant finishing is also softer than those.

Stone

The most important abrasive derived from stone is Staurolite. One of the best features this media offers is a smaller dust cloud.

Five ways to categorize each type of sandblasting media

There are five main ways to categorize sandblasting media, according to its features, as follow:

Shape

Each sandblasting media can come in one out of four possible shapes, which are angular, sub-angular, round, and sub-rounded. As the designation describes, angular media has sharper sides than the sub-angular, but both are used for aggressive abrasive blasting.

In the case of round and sub-rounded media, it happens the opposite way. They are used more often for mild abrasive blasting.

Hardness

Each type of sandblasting media has a different degree of hardness. That is useful because different hardness is required for different jobs. For example, the hardness needed for sandblasting wood is quite different than the one used for removing hard epoxy coatings.

Regarding hardness, the rule of thumb is to choose the abrasive with the minimum hardness required for the job.

Size

Sandblasting media is sized based on mesh screens ranging from 8 up to 400. With this we mean the size mesh the media particles will fit through. A mesh size of 10 has 10 holes per square inch. For this space, even the big particles can go through. Now, a mesh of 100 has 100 holes in the same square inch. Definitely, only smaller particles will go through this.

The experts’ opinion on this matter is to use the smallest media that will allow reaching the desired finish.

Density

Density refers to the mass per unit volume of any object. In sandblasting media, the denser the particle the more pressure upon impact will have. Then, denser media should be used for heavy-duty blasting jobs, while less dense media would be ideal for light-duty sandblasting.

As an example, the bulk density of abrasive media ranges from 50/lbs. per cubic foot (Plastic) up to 300/lbs. per cubic foot (Steel shot).

Recycling capabilities

The more media can be recycled, the more cost-efficient will be. Fortunately, most sandblasting media can be recycled. While the steel grits and shot are highly recyclable, their organic counterpart (walnut shells, corn cobs) are the lesser recyclable.

If you have the option to choose among several sandblasting media for your job, getting the most recyclable one will turn into a lot of savings. Nevertheless, all abrasives have a lifecycle and will break down at some point.

That is why many experts keep a working mix, adding new abrasives to the batch in use, instead of changing it all at once, to achieve consistent results.

Types of sandblasting media according to use

The following is a list of the 12 abrasives most widely used for sandblasting. For each one of them, we are explaining its main use and advantages.

Aluminum oxide

Aluminum oxide is one of the most commonly used sandblasting media worldwide. It is a very hard and angular media that can provide an extra coarse blast. For that reason is used mainly for deep cleaning, deburring, grinding, and polishing of hard constructed metals.

A few advantages of aluminum oxide are that is low in cost, comes in a variety of sizes, and can be recycled multiple times.

Steel shots and grits

Another widely used sandblasting media is steel. Steel shots are rounded, and steel grits are angular, but they are made out of the same material: carbon steel. They are used mainly for heavy-duty sandblasting, like preparation for epoxy coating, removing tough coatings, deburring, and so on.

Among the main advantages of this media are the high-quality and smooth resultant surface that produces. Also, there is a wide variety of sizes and hardness of this media, making it suitable for several different applications.

Glass beads

Glass beads are also among the most used sandblasting media, due to the fact that they are soft and produce a shiny appearance. When a metallic surface requires preparation for spray liquid painting or powder coating, glass beads are the go-to media. It is also used for removing rust and paint coatings.

Some advantages of glass beads are that are completely lead-free and can be recycled many times. Also, is provided in a wide range of sizes, from extra coarse to very fine.

Crushed Glass

Crushed glass is made out of discarded glass bottles and serves as an eco-friendly, general-purpose sandblasting media. It’s a semi-abrasive media useful for removing paints and, in some cases, fiberglass and wood.

It has a lot of advantages, like the fact that it is non-toxic, non-hazardous, and completely inert, so is safe to use around water. Also, since is clear, operators can see through what they are doing, improving productivity.

Silicon carbide

If you are looking for the current hardest media for sandblasting, look no further: it is silicon carbide. This material is a blocky grain texture that comes in several sizes, ranging from coarse grit to fine powder. While the coarse grit is used, for example, to remove mill scales, the fine powder is directed to polishing hard rock like granite.

Among the advantages of silicon carbide is that does not produce static electricity and, due to its hardness, sandblasting is performed faster.

Walnut shells

Walnut shells are an organic and biodegradable sandblasting media. Due to being a soft abrasive is used widely for cleaning, polishing, or preparing wood and for stripping automotive coatings.

Some of the more important advantages of walnut shells are being non-toxic, health-risk-free, and recyclable. This makes walnut shells both healthy and cost-saving media.

Corn cobs

Another organic sandblasting media is the corn cobs. Since is not very hard, it is used mostly for delicate surfaces, like wood and glass, or to remove mild coatings like grease, grime, or debris.

This is a biodegradable media made out of corn whose biggest advantages are being completely safe for operators and resistant to breakdown, which means that can be reusable. It only comes in extra-coarse size.

Staurolite

Staurolite is a silicate of silica and iron, mined from metamorphic rocks. Since is a sub-angular abrasive, is widely used for removing thinner or weakened coatings of paint, mainly in steel fabrication, storage tank and tower construction, and so on.

One advantage of this sandblasting media is that produces less dust than other abrasives, so operators are able to see how they are performing.

Plastics

Plastic media makes an excellent choice for stripping and cleaning applications involving aluminum composites and other delicate materials. If you need to remove organic coatings without damaging the underlying component surface, this is your go-to sandblasting media.

Some of the major advantages of plastic media are that they are available in all standard sizes, hardness, shape, and density, and even can be manufactured to suit different needs. They are also highly durable, recyclable, and completely free of silica.

Coal slag

Coal slag is a by-product of coal-fired electric power generation plants, that turns to be abrasive. From this material, there is a registered brand abrasive named Black Beauty.

This is a hard and fast sandblasting media. It is extremely coarse, low-dusting, and low-free silica. For these reasons is widely used in the shipyard and marine industry, as well as in industrial maintenance and repairs.

Soda

Soda blasting is an abrasive made out of baking soda or bicarbonate of soda. This media is used primarily to clean surfaces. Since is also a deodorizer, is ideal for cleaning up after a fire or removing mold. Due to its fragility, it will break when impacting the surface, so is going to create a lot of dust and it won’t be recyclable.

Some advantages of soda blasting are its safety on surfaces. Can be used on glass, rubber, chrome, and other delicate surfaces. It won’t produce heat and it won’t warp the surfaces.

Garnet

Garnet is another sandblasting media of natural origin. Due to its angular shape, sandblasting jobs with garnet media are fast, and surfaces cleaned with it tend to last clean longer than average. Since is highly inert is safe to use around bodies of water. It leaves less porosity and smoother finishes.

Some of the biggest advantages of garnet are that is non-toxic, low-dusting, and low-consuming. Besides, can be reused a number of times more than other media.

You are not alone in this

We, the people at Ifexport have been working with industrial processes, like sandblasting, since 1979. So, we can tell you one thing or two about sandblasting media.

Helping our clients to get covered with their sandblasting needs is one of our goals. We can’t wait to apply our expertise to your workshop also.

This Post Has One Comment

We found your post to be very informative since it explains and categorizes different types of sandblasting media. One of my cousins is investing in renovating an industrial building and needs to find sandblasting equipment to prepare its surface for new paint. I’ll be sure to share your tips with him so he can choose the right type of abrasive media.