There are dozens of spray guns for automotive for any paint shop owner or painter to choose from. Indeed, it has become a highly competitive niche within finishing, creating a whole new category among manufacturers.

While recognizing that, we also can perceive that paint shop owners, managers, and painters can be better informed to take decisions regarding what equipment to get, how to use it, and how to maintain it. That is the scope of this article.

What are spray guns

Spray guns are tools that use compressed air to atomize and apply paints, coatings, and finishes onto surfaces. Some of the coatings that can be applied with a spray gun are materials such as varnish, paints, or adhesive.

They are essential professional tools that allow fast, consistent application of liquid paint coatings to create smooth, uniform finishes. They atomize paint for efficient transfer onto the surface.

Even though spray guns can be used for a variety of applications, including furniture finishing, and home improvement projects, in this article we are going to focus on spray guns for automotive finishing or refinishing.

Types of spray guns

There are three main types of spray guns: airless, pneumatic, and HVLP (high-volume, low-pressure).

- Airless spray guns use high pressure to force the liquid through a nozzle, creating a fine mist

- Pneumatic spray guns use compressed air to atomize the liquid

- HVLP spray guns use a combination of high volume and low pressure to create a very fine mist

Spray guns come in a variety of sizes and styles. The structure and weight vary greatly among the models available. So, it is important to choose the right one for the job.

When using a spray gun, regardless of the specific purpose, it is important to wear safety glasses and a respirator to protect yourself from the paint mist. It is also essential to follow the manufacturer’s instructions to ensure that the spray gun is used properly.

Key points about spray guns

- They use either compressed air (conventional guns) or hydraulic pressure (airless guns) to atomize the paint into a fine mist

- The paint is supplied from a reservoir like a cup or canister and flows through the gun nozzle when the trigger is pulled

- Spray guns allow paint to be applied in an even, uniform layer over large surface areas much faster than brushing or rolling

- Different types of spray guns are designed for use with different materials (primers, paints, clearcoats, etc.)

- Spray guns for automotive painting are optimized to atomize paints like lacquers, enamels, urethanes, and basecoat/clearcoat systems

- The pattern of paint coming from the spray gun can be adjusted from circular to wide fan shapes using air caps and flow controls

- Good spray technique is important for proper coverage, an even finish, and minimal paint waste

The history behind spray guns for automotive

The history of spray guns as a device can be traced back to the early 1800s. Nevertheless, regarding spray guns for automotive, in 1907 Thomas DeVilbiss invented the first air-powered spray gun, which was quickly adopted by the automotive industry. It combined air and fluid nozzles and it was used for painting the mass-produced Ford Model T’s.

These early spray guns were relatively inefficient, and they produced a lot of overspray. However, they were a significant improvement over previous methods of painting cars, which were often done by hand with brushes.

In the 1930s, high-volume, low-pressure (HVLP) spray guns were developed. HVLP spray guns use a lower pressure of air than conventional spray guns, which results in a finer mist of paint. This produces a more uniform finish with less overspray. HVLP spray guns quickly became the standard for automotive painting, and they are still used today.

During the 1960’s and 1970’s the world saw new spray gun designs focused on better ergonomics and comfort for prolonged use. Compliant spray guns developed to work with new EPA air quality regulations. Additional innovations in precision air and fluid nozzles improved paint atomization further.

Later, in the 1980s, electronic controls were introduced to spray guns. These controls allow the operator to precisely control the flow of paint and air, which results in a more consistent finish. Electronically controlled spray guns are now the standard for automotive painting, and they are used by both professional and amateur painters.

In recent years, advanced fluid dynamics increase atomization while reducing overspray. Digital controls and sensors were added to automotive spray guns. Current spray guns for automotive utilize lightweight composites and have computerized controls and feedback systems.

Why are special spray guns for automotive needed?

There are a few reasons why special spray guns for automotive applications are needed:

Thinner paint: Automotive paint is typically much thinner than other types of paint, so it requires a spray gun that can atomize the paint properly. This ensures that the paint will dry evenly and smoothly, without any runs or drips.

High-volume, low-pressure (HVLP) spray: HVLP spray guns use less air pressure than traditional spray guns, which helps to reduce overspray and waste. This is important for automotive applications, where the cost of paint can be high.

Controlled fan pattern: Automotive spray guns typically have a controlled fan pattern, which ensures that the paint is applied evenly over a large area. This is important for getting a smooth, professional finish.

Finish quality: We all want our machines to shine. Automotive finishes require an extremely smooth, flawless, uniform look. Spray guns for automotive must atomize paint finely.

Ergonomics: Spraying cars requires hours of continual use, so lightweight, balanced designs prevent fatigue. The trigger as well must be soft, for ease of use.

Durability: Automotive spray guns need to be durable enough to withstand the harsh conditions of the automotive industry. This includes exposure to chemicals, solvents, and extreme temperatures.

Ease of maintenance: Quick disassembly for cleaning and parts replacement helps increase painter productivity.

Flexibility: Ability to handle a range of viscosities and adjust spray patterns is needed.

In addition to these factors, special spray guns for automotive applications may also have features that are specific to the type of paint being used, such as a built-in filter or a special nozzle design.

Not all painting shops are created equal

When it comes to automotive painting, the shops’ needs are quite wide. So, let’s categorize all the shops where cars are painted to set a pattern regarding their needs.

The automotive industry

This is the section of the manufacturing plan where the painting of the vehicles in production takes place. The finish must be impeccable, because every driver wants his machine to look great from day one.

Also, during the production of the vehicles, some scratches might happen, especially during the testing phase. So, some touch paint might be needed before the units leave the plant.

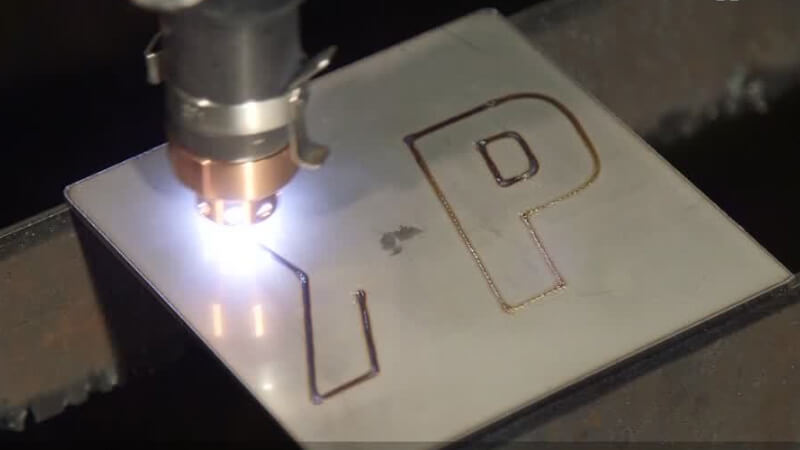

In almost every assembly line in the world the painting is done by means of automated spray guns. Some brands like DeVilbiss, Binks, and Ransburg have robotic spray guns in their catalog.

For some special coatings, some curing might take place, which can be done using BGK’s ovens. When electrostatic painting is required, Ransburg automated spray guns can supply the need.

The high-class paint shops

They are the ones that paint super high-profile vehicles such as Lamborghini, Porshe, Rolls Royce, Ferrari and others. In some places where the amount of these vehicles is lower, they can also take care of other high-profile manufacturers like BMW, Mercedes Benz, Audi, Land Rover, and the like.

At any rate, the finish these painters must achieve should be outstanding. The quality of the coatings and the equipment must be the highest. In most cases they use cabins that allow them to reach the best finish possible regardless of the environmental conditions.

The high-volume paint shops

In this case, more than an exceptional quality, these body shops are focused on quantity. They might be part of car dealers or insurances paint shops.

On average they might be painting some 100 vehicles per month. They might reach higher numbers, achieving to provide service to some 250 vehicles per month in some cases.

The main need for this type of auto body shop is efficiency. Of course, they also need quality, but the coatings they handle and the vehicles they paint are rather medium to low profile.

As an example, some of these auto body shops can paint trucks, taxis, and commercial vehicles.

The medium size paint shops

Here we are referring to the auto body shops that paint something between 10 to 100 vehicles every month. They might have a group of professional painters who need to be efficient, but also offer good quality.

Since the range is wide, their specific needs might vary greatly as well. Since they are smaller than the dealers’ paint shops, their customers expect better service and high quality. They might be willing to pay more for a better coating and customized finish.

The small paint shops

This auto body repair shops are the one painting 10 vehicles or less every month. In most cases the painter’s team is composed of the owner and a few more. Many of these types of auto refinishing shops are family companies focused on service over production.

They need high quality spray guns that allow them to achieve an outstanding finish. Since their work capital is limited, they cannot afford to get new equipment once and again, but they need to rely on good spray guns that help them to save on coatings, time, and offer an excellent service.

Regardless of the specific needs you might have, based on the type of auto body shop you own or run, DeVilbiss, Binks, Ransburg, BGK and Hosco, as part of a group of fluid technology brands, have a solution that can be customized to you. Feel free to reach out to any of our advisors to find out what works best for you.

The more important features for spray guns for automotive

We already saw that spray guns for automotive are a separate category within the universe of industrial finishing. Now, let’s review some features that every spray gun for automotive must have.

Fine atomization

Fine atomization is important for a spray gun for automotive because it produces a smooth, even finish with less overspray. This is important for several reasons, including:

It produces a more professional-looking finish: A fine finish will hide imperfections in the underlying surface and give the car a uniform, high-quality appearance.

It helps to reduce the amount of paint used: Overspray can be wasteful and expensive, so fine atomization helps to ensure that the paint is used efficiently.

It creates a healthier work environment: Overspray can contain harmful chemicals, so fine atomization helps to reduce the amount of these chemicals that are released into the air.

It is safer for the operator: Overspray can also be a safety hazard, so fine atomization helps to reduce the risk of the operator inhaling or being in contact with harmful chemicals.

In addition to these benefits, fine atomization can also help to improve the drying time of the paint, which can shorten the overall painting process.

Lightweight

It makes a lot of sense for a spray gun for automotive to be lightweight, for the following reasons:

Reduced fatigue: When using a heavy spray gun, the operator can experience fatigue in their arms and shoulders. This can lead to poor painting technique and can also increase the risk of injury.

A lightweight spray gun will help to reduce fatigue and allow the operator to work for longer periods of time without experiencing discomfort.

Improved maneuverability: A lightweight spray gun is easier to maneuver, which can help the operator to get into tight spaces and to paint more accurately. This is especially important when painting complex surfaces, such as those found on cars.

Increased comfort: A lightweight spray gun is simply more comfortable to use. This can help the operator to focus on the task at hand and to produce a better-quality finish.

Storage: A lightweight spray gun can also be more portable and easier to store. This can be a major advantage for professional painters who need to transport their equipment between jobs.

Soft trigger

A soft trigger on a spray gun for automotive is important for a few reasons:

It reduces fatigue: When using a spray gun, the operator’s finger is constantly on the trigger. A soft trigger will make it easier to hold down the trigger for long periods of time, which can help to reduce fatigue.

It allows for more precise control: A soft trigger allows the operator to control the amount of paint that is released more precisely. This can be helpful when painting small areas or when trying to achieve a specific finish.

When doing touch-ups, a soft trigger allows you to spray just the exact amount of paint the operator needs, in a small area.

It is more comfortable to use: Simply put, a soft trigger is more comfortable to use than a hard trigger. This can help the operator to focus on the task at hand and to produce a better-quality finish.

It prevents accidents: For example, if the operator accidentally slips and pulls the trigger too far, a soft trigger will help to prevent the gun from spraying a large amount of paint.

Good quality body

A good quality body on a spray gun for automotive is important for a few reasons:

It ensures durability: A good quality body will be able to withstand the rigors of use, such as being dropped or knocked over. This is important because a damaged spray gun can produce uneven or poor-quality finishes.

A good spray gun for automotive is made to last a long time. If you find yourself buying spray guns very frequently, you need to upgrade the quality of the spray guns you are using.

It provides a better finish: A good quality body will help to ensure that the paint is sprayed evenly and smoothly. This is important because an uneven or poor-quality finish can be unsightly and can also lead to problems with the paint’s durability.

It is easier to clean: A good quality body will be easier to clean. This is important because a dirty spray gun can clog the nozzle and prevent the paint from atomizing properly.

It is more comfortable to use: A comfortable spray gun will help the painter to work for longer periods of time without experiencing fatigue, so it is more comfortable.

Air hoses

Air supply hoses are not actually part of a gun, but it is essential to have the correct hose for excellent results.

If the distance from the air filter outlet to the gun is less than 25 feet (7.5 meters), an 8-millimeter (5/16 inch) inside diameter air hose should be used.

In case the distance from the air filter outlet to the gun is between 25 to 50 feet (7.5 to 15 meters), a 10-millimeter (3/8 inch) inside diameter air hose should be used.

Hoses longer than 50 feet (15 meters) are not usually used. But if that is a need in your paint shop, contact us for recommendations.

Each spray gun for automotive has a specific task

They might look quite similar, but spray guns for automotive can be grouped in 4 basic categories, which are primers (the background coating onto which the color is added), basecoats (the ones used to paint the base color or main coating), clearcoat (the ones used for applying the varnishes or similar top coatings), and touch-ups (the ones used to small repairs)

Let’s see some features each one of these 4 spray guns for automotive have.

Primers

Nozzle size: Primers are viscous coatings that have a high solids content. To apply them, a nozzle size of 1.7 mm to 2.2 mm should be used.

Low air pressure: To apply primers requires a lower air pressure than others, usually around 10 psi or less. This is due to the viscosity of the coating.

Adjustable fan: Since the purpose of primers is to cover repairs made to the surfaces to be painted, it is ideal to use a wide fan so that the area is covered in the shortest possible time. This also reduces overspray.

Basecoat

Nozzle size: The nozzle opening size affects paint atomization. For basecoats, a 1.2 mm to 1.4 mm nozzle size provides fine atomization for smooth coverage.

Low air pressure: Higher air pressure causes the paint to be applied too heavily. If the spray gun uses less air, less coating will be lost as overspray. This is important for environmental and economic reasons. Basecoats spray guns require lower air pressure than others, typically around 10 psi or less.

Adjustable fan pattern: Basecoat spray guns should allow you to adjust the fan pattern from a tight circular pattern to a wide fan. This way you control the area being painted and reduce overspray. This ensures that the paint is applied evenly and smoothly, resulting in a professional-looking finish.

Air and fluid adjustments: Knobs or dials (depending on being digital or analog) allow you to easily fine tune the air pressure and paint flow without changing the setup, ensuring that the spray gun is operating at the correct pressure.

Clearcoat

Nozzle size: Larger nozzle openings like 1.4 mm, 1.6 mm or 1.8 mm are preferred for clearcoats to allow heavier paint flow and wet coats.

Higher air pressure: Clearcoats are applied at higher pressures than that of basecoat spray guns, typically 10-15 psi. The spray gun should be able to handle higher pressures without over-atomizing the paint.

Fan pattern control: A clearcoat spray gun should allow you to control the fan size from a round pattern to a wide fan of 10 inches or more.

Air and fluid adjustments: Separate controls help fine tune the air and fluid to optimize the spray pattern and flow for clearcoats. In the newer models, a digital pressure gauge helps you to keep in check that the spray gun is operating at the correct pressure.

Touch-up

Small size: Touch-up spray guns are typically smaller than regular spray guns, making them easier to handle and maneuver in tight spaces.

Small cup capacity: Since touch-ups use less paint, a small 6–8-ounce cup is ideal to hold just enough material. Larger cups lead to more waste.

Small nozzle sizes: Nozzles around 0.5-1.0 mm produce a lower paint output suitable for small touch-up areas.

Fine atomization: Touch-up work requires very fine finish control, so the spray gun needs to finely atomize paint at low air pressures. The good ones are optimized for 10 psi or even less.

Reduced overspray: Fan pattern control allows reducing the spray width to concentrate paint only where needed and minimize overspray. This will help to ensure that the coating is applied evenly and smoothly, resulting in a professional-looking finish.

How to choose the right spray gun for automotive

This is probably the most important question in this article. At the end of the day, you want to have as much information as possible, to take the best decision. Well, now we are going to consider 3 key factors to decide what spray gun for automotive to buy.

Type of coating you are going to apply (water, solvent)

To optimize performance, the fluid delivery and spray characteristics are tuned differently in spray guns designed specifically for water or solvent-based paints. Let’s see some differences between these 2 options.

Fluid Passages and seals: Passages in water-based spray guns are often coated to prevent corrosion from water. Solvent-based spray guns need solvent-resistant coatings. In the same manner, seals and packings in water-based spray guns are made from materials resistant to water and high pH. Solvent-based spray guns use solvent-resistant seals.

Fluid Nozzles: Nozzles in water-based spray guns are optimized to atomize thicker, slower drying paints. Solvent-based nozzles work better for thinner paints.

Overspray: Water-based paint overspray dries into a powder while solvent-based coatings overspray dries into an oily mist. The air caps are different in each case.

Cleaning: Water-based spray guns are cleaned with water or mild solvents. Solvent-based spray guns require stronger lacquer thinners and longer cleaning times.

Environmental: Water-based spray guns produce less VOC emissions and waste than solvent-based spray guns.

Cost: Good water-based spray guns cost slightly more than comparable solvent-based spray guns in many cases.

Despite these differences, what really defines what spray gun for refinishing you will get is what type of coating you do apply.

Purpose (primer, base, clear)

When it comes to spray guns for automotive, there are 3 possibilities: primers, basecoats or clearcoats. Let’s see the main features of each one.

Primers:

- Layer of 10 to 15 microns

- Light colors (such as gray and white)

- High solids content

- Their purpose is to coat the sheet metal work done on the vehicles and prepare them for color painting

- Must be sanded to prepare for the next coat of paint

- Some new primers can correct imperfections so that sanding is not necessary

Basecoats:

- Layer of 15 to 30 microns

- Contain color pigments and tinting pearls/flakes to achieve the desired paint color and effects

- Typically, a water-based or solvent-based acrylic lacquer formula

- Sprayed on first to provide color before clear coating

- Require a later clear coat for gloss, depth, and protection

- Often require multiple coats for full, even coverage due to translucent nature

Clearcoats:

- Layer of 30 to 50 microns

- Contain no color pigments, designed to be transparent

- Usually a high-gloss polyurethane or acrylic urethane formulation

- Sprayed over the base color coat

- Provides gloss, DOI (distinctness of image), protection from UV rays

- Can be layered to increase depth and wetness of the paint job

- Requires sanding and polishing to achieve final gloss

So, in summary, basecoats provide color while clearcoats provide gloss and protection. The combination gives the high-quality finish expected from modern automotive refinishing. You will need one spray gun of each type for automotive painting.

Why a spray gun for basecoat cannot be used for clearcoat?

While technically speaking it is possible to use one spray gun, the differences in basecoat and clearcoat materials mean optimal, professional results are achieved by using separate, dedicated spray guns for each. Doing so reduces potential issues. There are a few key reasons why dedicated spray guns for basecoat and clearcoat are recommended rather than using the same for both:

Different fluid tip sizes: Basecoats require smaller tips (1.2-1.4 mm) than clearcoats (1.4-1.8 mm) for proper atomization.

Precise airflow needs: Bleeder style air valves on basecoat spray guns allow fine tuning that is not needed for clearcoats.

Contamination risks: Residual basecoat trapped in the spray gun can contaminate the clearcoat, affecting appearance.

Cleaning challenges: Basecoat color trapped in a spray gun is harder to fully clean out before spraying clearcoat.

Basecoat drying: Spray guns optimized for basecoat have better fluid passages to prevent premature drying.

Pattern control: Wider fan patterns needed for base don’t work as well for clearing.

Different viscosities: Basecoats are thinner than high solids clearcoats.

Metallic control: Basecoat spray guns optimized to apply metallic colors evenly.

Cost factors: Additional dedicated spray guns allow technicians to work faster.

How to use a spray gun for automotive

Proper spray gun technique, cleaning, and maintenance will result in professional quality paint jobs with maximum efficiency. Of course, learning how to use a spray gun for automotive is not something that you can learn just by reading a single article. Consider these just a few tips that some experts give on properly using a spray gun for automotive refinishing:

- Use the spray gun according to its purpose

- Confirm that the compressor you have can provide the amount of air the spray gun needs. Each spray gun has different air requirements, depending on the air layer

- Use the right accessories, like the Snap-n-flow, to ease the paint jobs

- Carefully mix and strain the paint material to remove any particles that could clog the spray gun

- Adjust the fluid nozzle size and pattern controls to suit the type of coating being sprayed

- Set the air pressure at the gun between 28-40 PSI for HVLP or 10 PSI or less for LVLP

- Position the gun perpendicular to the surface at a distance of 6-8 inches when spraying

- Use smooth, even strokes over the full length of the area being painted. Overlap passes by 30%

- Keep the gun the same distance from the surface and maintain consistent speed for even coverage

- Periodically blow excess paint out of the spray gun nozzle to avoid drips and runs

- Clean the spray gun thoroughly after every use, taking care to remove paint from the fluid tip and air cap

- Inspect fluid tips regularly and replace them immediately if there is any damage or wear

- Prevent water, oil and other contaminants from entering the air supply to the spray gun

- Wear proper PPE – spray suits, organic vapor respirator, gloves, eye protection

- Allow sufficient ventilation and paint booth filters when spraying

What is Snap-n-flow?

Snap-n-Flow is a disposable cup system for making automotive refinishing easier, faster and more efficient. The system offers many benefits to body shops and refinishers, including:

- Requires fewer steps

- Improves color matching

- Minimizes paint usage

- Creates less mess and cleaning is faster

- Offers easy paint storage options

- Offers greater savings in materials and time

How to maintain a spray gun for automotive

Proper maintenance and care will maximize a spray gun’s longevity while maintaining optimal spray performance. Here are some tips for properly maintaining an automotive refinishing spray gun:

- Clean thoroughly after each use. Disassemble, rinse all parts in solvent, lubricate, and reassemble

- Inspect the fluid tip often. Replace it immediately if there is any damage or wear to the edges

- Lubricate moving parts like the trigger, air valve, and needle packing regularly. Use an air tool oil

- Check the air filter and replace it if dirty. A filter prevents moisture and debris from entering

- Tighten any loose hose fittings, caps, rings, or connections. Prevent air and fluid leaks

- Test the spray pattern periodically on cardboard. Adjust if the pattern becomes uneven

- Store the spray gun upright and with a moisture cap on the fluid tip to prevent spills and tip drying

- Replace worn gaskets, o-rings, packings, and seals when rebuilding kits are available

- Keep spare parts like fluid tips, needles, and cup seals on hand so the spray gun is always ready to work

- Follow the manufacturer’s rebuild instructions to periodically refresh the spray gun’s components

- Avoid soaking the entire spray gun in solvent baths to prevent damage to internal components.

Tips and tricks for cleaning

Proper cleaning maintains the spray gun’s performance and prevents premature wear. It’s essential after every use. Here are some steps for properly cleaning an automotive spray gun:

- Disassemble the gun: Remove fluid tip, air cap, fluid nozzle, and cup. Break down into individual parts

- Clean cup first: Rinse cup thoroughly with appropriate solvent like gun wash or thinner. Wipe interior with rags

- Use compatible solvents: Refer to spray gun manual for recommended cleaning products. Avoid incompatible solvents

- Scrub passages: Use detail brushes to scrub any paint residue from fluid passages and nooks

- Clean air cap: Remove dried paint from the air cap using toothpicks, taking care not to damage it

- Rinse parts: Submerge disassembled parts in solvent and agitate. Rinse with clean solvent

- Blow dry: Use compressed air to blow residual solvent out of gun passages, cap, and recesses

- Lubricate: Apply a small amount of gun lube to the needle, air valve, and packing. Reassemble wet

- Filter solvents: Used solvents should be filtered and stored in sealed containers for reuse

- Check operation: Test spray pattern & flow on cardboard. Adjust if needed

Why DeVilbiss spray guns for automotive are so famous

We have concluded that, hands down, DeVilbiss spray guns are the best in automotive refinishing for several good reasons:

Proven reliability: DeVilbiss guns are precision-made to withstand constant professional use for many years.

Excellent finish quality: Optimized air caps and fluid tips provide superb atomization for flawless finishes.

Ergonomic designs: Lightweight composite bodies reduce fatigue during prolonged painting sessions.

Easy maintenance: Simple construction and parts breakdown make cleaning and repairs straightforward.

Wide range of spray guns: DeVilbiss offers specialized models for primers, basecoats, clears, etc.

Latest technologies: DeVilbiss incorporates innovations like digital gauges and controls on higher-end models.

Durable construction: Parts like anodized bodies, stainless steel passages, and wear-resistant fluid tips promote longevity.

Established reputation: Trusted brand in the automotive refinishing industry with decades of experience.

Reasonable pricing: DeVilbiss spray guns provide excellent value for the performance and results achieved.

Excellent support: Readily available rebuild kits, manuals, and local sales/service.

The combination of proven results, innovative features, competitive pricing, and strong reputation is why DeVilbiss remains a go-to spray gun brand for so many professional automotive painters and body shops.

Contact us to provide you with the best spray guns for refinishing in the market.