When we think of TIG welding machines immediately the range of possibilities opens wide. That is because the TIG welding process is, arguably, the most used welding process in the world.

Still, most professional welders have only one TIG welding machine, because they might be expensive. So, with so much TIG welding equipment available, but the need to choose only one, which one are you going to buy? We hope this article will help you to define that. Let’s start with the basics.

Good brands produce good products

You might be familiar with this concept. We can see that clearly in the automotive industry. Some automotive manufacturers are high end and their vehicles cost considerably more than other brands. You are expected to pay more for a Tesla than for a Ford.

Partially, the difference between the two brands is the quality process in their manufacturing process. In higher-end vehicles, every detail is cared for and is a product built to last. In welding machines, like any other product segment, happens the same.

So, if you want quality, it is expected a higher price. But don’t despair, hard competition urges even worldwide known manufacturers to lower prices, in order to keep selling. So this balance the equation.

Since we know how much you appreciate good quality, we are limiting this article to good-quality products. Let’s get started with our 5ft place.

5th place: Ronch TIG 200 AC/DC

The Ronch 200TIGP AC/DC is an inverter for AC/DC HF TIG welding for tungsten and electrodes. It comes equipped with protection systems for temperature, voltage (V), and current (A) sensors.

Highlights of the Ronch TIG 200 AC/DC

- Processes: DC MMA – DC TIG – DC Pulse TIG – AC MMA – AC TIG – AC Pulse TIG

- Current Type: AC/DC

- Input Hz: 50/60Hz

- Input Voltage: 220V

- Shipping Dimensions: 17 x 6 x 11 inches

- Weight: 14 pounds

A few details about the Ronch TIG 200 AC/DC

The Ronch TIG200 AC/DC welding machine adopts the latest pulse width modulation (PWM) technology and insulated gate bipolar transistor (IGBT) power module, which can change work frequency to medium frequency so as to replace the traditional hulking work frequency transformer with the cabinet medium frequency transformer.

This welding machine is characterized as portable, small in size, lightweight, low consumption and etc. The parameters of TIG200E AC/DC on the front panel all can be adjusted continuously, such as:

- Start current

- Crater arc current

- Welding current

- Base current

- Duty ratio

- Upslope time

- Downslope time

- Pre-gas and post-gas

- Pulse frequency

- AC frequency

- Balance

- Hot start

- Arc force

- Arc length

When welding, it takes high frequency and high voltage for arc igniting to ensure the success ratio of igniting arc.

Features of the Ronch TIG 200 AC/DC

- MCU control system, responds immediately to any changes

- High frequency and high voltage for arc igniting to ensure the success ratio of igniting arc. The reverse polarity ignition ensures good ignition behavior in TIG-AC welding

- Avoid AC arc-break with special means, even if arc-break occurs the HF will keep the arc stable

- The pedal controls the welding current

- TIG/DC operation: If the tungsten electrode touches the workpiece when welding, the current will drop to short-circuit current to protect the tungsten

- Intelligent protection: over-voltage, over-current, over-heat when the problems listed before occurred, the alarm lamp on the front panel will be on and the output current will be cut off. It can self-protect and prolong the equipment’s life

- Double purposes: AC inverter TIG/MMA and DC inverter TIG/MMA

- Excellent performance on Al-alloy, carbon steel, stainless steel, and titanium

4th place: Ronch Raptor Duty 350 TIG AC/DC

The Ronch 350TIG AC/DC is an inverter for AC/DC HF TIG welding for tungsten and electrodes. It comes equipped with protection systems for temperature, voltage (V), and current (A) sensors.

Highlights of the Ronch Raptor Duty 350 TIG AC/DC

- Processes: DC MMA – DC TIG – DC Pulse TIG – AC MMA – AC TIG – AC Pulse TIG

- Current Type: AC/DC

- Input Hz: 50/60Hz

- Input Voltage: 220V – 240V

- Shipping Dimensions: 22 x 10 x 18 inches

- Weight: 58 pounds

A few details about the Ronch Raptor Duty 350 TIG AC/DC

The Ronch Raptor Duty 350 TIG AC/DC adopts the latest Pulse Width Modulation (PWM) technology and the Insulated Gate Bipolar Transistor (IGBT) power modules.

It uses switching frequencies in the 20KHz-50KHz ranges so as to replace the traditional line-frequency transformer-type welding machines. This welding machine is characterized by portability, small size, lightweight, low energy consumption and noise, etc.

The parameters of the machine on the front panel all can be adjusted continuously, such as:

- Start current

- Crater arc current

- Welding current

- Base current

- Duty ratio

- Upslope time

- Downslope time

- Pre-gas and post-gas

- Pulse frequency

- AC frequency

- Balance

- Hot start

- Arc force

- Arc length

When welding, it takes high frequency and high voltage for arc igniting to ensure the success ratio of igniting arc.

Features of the Ronch Raptor Duty 350 TIG AC/DC

- MCU control system, responds immediately to any changes

- High frequency and high voltage for arc igniting to ensure the success ratio of igniting arc. The reverse polarity ignition ensures good ignition behavior in TIG-AC welding

- Avoid AC arc-break with special means, even if arc-break occurs the HF will keep the arc stable

- The pedal controls the welding current

- TIG/DC operation, If the tungsten electrode touches the workpiece when welding, the current will drop to short-circuit current to protect the tungsten

- Intelligent protection: over-voltage, over-current, over-heat, when the problems listed before occurred, the alarm lamp on the front panel will be on and the output current will be cut off. It can self-protect and prolong the equipment’s life

- Double purposes: AC inverter TIG/MMA and DC inverter TIG/MMA

- Excellent performance on Al-alloy, carbon steel, stainless steel, and titanium.

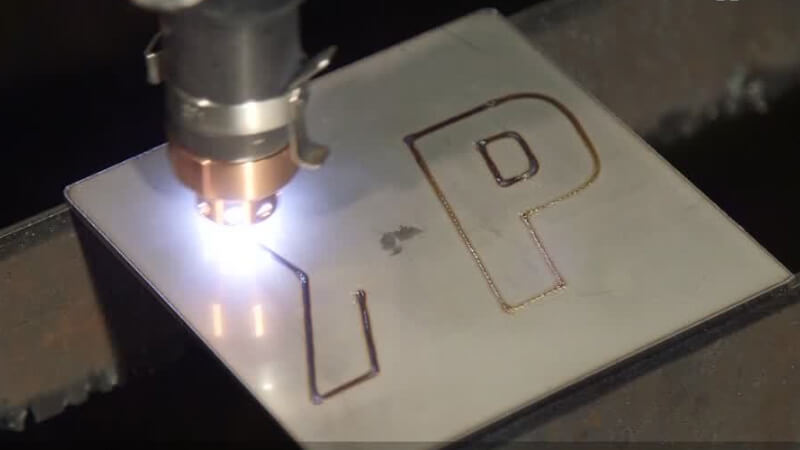

Let's use the new technologies

Automation is the present and the future

3rd place: Miller Maxstar 280

The Maxstar 280 Series is a powerful combination of capability and portability. Weighing only 47 pounds, it can weld up to 3/8″ thick material. The DC TIG/Stick power sources feature an energy-efficient inverter design and Auto-Line™ technology.

Highlights of the Miller Maxstar 280

- Processes: Air Carbon Arc Cutting and Gouging (CAC-A), Stick (SMAW), TIG (GTAW), TIG DC (GTAW-DC)

- Current Type: DC

- Input Hz: 50/60 Hz

- Input Voltage: 208 V – 220/230/240 V – 380/400 V – 460/480 V – 575 V

- Weight: 47 pounds

A few details about the Miller Maxstar 280

Base and Deluxe Models Available: The base model provides essential TIG and Stick functions and provides operator-friendly, menu-driven features. The DX model adds extended ranges to the sequencer and full trigger options, preflow and pulser functions.

Portable with adjustable shoulder strap: Weighing in at just 47 pounds, the Maxstar 280 is extremely portable and easy to transport featuring dual carry handles and a carrying strap.

Upgradeable and Expandable: Front panel memory card data port provides the ability to easily upgrade software and expand product features.

Cooler Power Supply (CPS): An integrated 120-volt dedicated-use receptacle to power the Coolmate™ 1.3. The power switch on the Maxstar also activates the receptacle to help prevent torch failure. Available on some models.

Auto-Line Power Management Technology: Allows hookup to either single-phase or three-phase electrical input from 208-575 V with no manual linking, providing convenience in any job setting. An ideal solution for dirty or unreliable input power.

Pro-Set Feature: This feature eliminates the guesswork when setting weld parameters. Use Pro-Set when you want the speed, convenience, and confidence of pre-set controls.

Simply select the feature and adjust until Pro-Set appears on the display. The Pro-Set feature is available for Balance, Frequency, Pulse, and DIG parameters.

Stick Features: Tailored arc control (DIG) allows the arc characteristics to be changed for specific applications and electrodes. Smooth running 7018 or stiffer, more penetrating 6010. Hot Start™ adaptive control provides positive arc starts without sticking.

Weldcraft® W-280 (WP-280) TIG Torch: Two-piece torch head and exclusive Super Cool™ Technology provides an additional surface area to increase cooling efficiency and capacity.

The torch body includes an anti-rotation feature and multi-position locking to prevent handle movement during welding and improve operator control. Mechanical fittings provide a secure gas and water connection to prevent leakage and allow easy hose replacement.

Features of the Miller Maxstar 280

- Weldable Metals: Specialty Metals, Stainless Steel, Steel

- Material Thickness: Steel 0.004 in. (0.1 mm) – 3/8 in. (9.5 mm)

- Input Phase: 1- and 3-Phase

- Amperage: 1 A – 280 A

2nd place: Miller Syncrowave 300

For fabricators who need more TIG welding productivity and lower operating costs, the new Miller Syncrowave 300 welding machine is the energy-efficient TIG welding power source that makes it easier for any welder to get more work done.

Highlights of the Miller Syncrowave 300

- Processes: Aluminum Welding, Stick (SMAW), TIG (GTAW), TIG AC (GTAW-AC), TIG DC (GTAW-DC)

- Current Type: AC / DC

- Input Hz: 50/60 Hz

- Input Voltage: 208 V – 220/230/240 V – 460/480 V

A few details about the Miller Syncrowave 300

Pro-Set™ Feature: Eliminates the guesswork when setting TIG weld parameters. Just one touch gives you the speed, convenience, and confidence of preset controls.

Auto-Link: The circuit automatically links the power source to the primary voltage being applied (208/240/480 V, single- or three-phase).

Simple to install: Accepts either single- or three-phase input power.

Smaller Footprint: Smaller, lighter machines are easier to move around and improve workplace conditions.

Energy efficient: Save up to 33 percent on energy costs versus outdated welding equipment.

Better Arc Performance: Deliver more stable arcs and better arc-starting characteristics, making it easy for any welder to get more work done and do better work.

Easy to use: Intuitive user interface is simple to understand making it easy to adjust parameters. This means less time training new employees so more work gets done.

Features of the Miller Syncrowave 300

- Weldable Metals: Aluminum, Stainless Steel, Steel

- Material Thickness: Aluminum 0.015 in. (0.4 mm) – 3/8 in. (9.5 mm) / Steel 0.012 in. (0.3 mm) – 1/2 in. (12.7 mm)

- Input Phase: 1- and 3-Phase

- Amperage: 5 A (Min) – 300 A (Max)

1st place: Miller Dynasty 800

The Miller Dynasty 800 is a powerful, compact power source capable of welding up to 1″ aluminum. Total arc control provides maximum productivity and weld quality while conserving energy compared to traditional welding machines.

Highlights of the Miller Dynasty 800

- Processes: Air Carbon Arc Cutting and Gouging (CAC-A), Aluminum Welding, Pulsed TIG (GTAW-P), Stick (SMAW), TIG AC (GTAW-AC), TIG DC (GTAW-DC), TIG (GTAW)

- Current Type: AC / DC

- Input Hz: 50/60 Hz

- Input Voltage: 208 V – 220/230/240 V – 380/400 V – 460/480 V – 575 V

- Shipping Dimensions: 14 x 35 x 22 inches

- Weight: 198 pounds

A few details about the Miller Dynasty 800

AC Features: AC TIG Features Independent amplitude/amperage control allows EP and EN amperages to be set independently to precisely control heat input to the work and electrode.

Extended AC Balance (30–99%) controls the amount of oxide cleaning (amperage time in EN) which is essential for high-quality welds on aluminum. AC frequency (20–400 Hz) controls the width of the arc cone and the force of the arc.

DC TIG Features: Exceptionally smooth and precise arc for welding exotic materials.

High-speed DC TIG pulse controls: Pulse frequency capable of pulsing 5000 pulses per second. Pulsing adds arc stability, reduces heat input and warpage, and can increase travel speeds. Other parameters include peak amperage, peak time, and background amperage.

AC Waveforms: Advance Squarewave provides a fast freezing puddle, deep penetration, and fast travel speeds. Soft Squarewave is used for a soft buttery arc with maximum puddle control and good wetting action. The sine wave is for customers that like a traditional arc. It is quiet with good wetting. Triangular wave reduces the heat input and is good on thin aluminum. It provides fast travel speeds.

Blue Lightning™ – High-Frequency Arc Starter: For more consistent non-contact starts and greater reliability compared to traditional HF arc starters.

Program memory: Program memory features 9 independent program memories that maintain/save your parameters.

Cooler Power Supply (CPS): An integrated 120-volt dedicated-use receptacle to power the Coolmate™ 3.5. The power switch on the Dynasty also activates the receptacle to help prevent torch failure.

Meter Calibration: Allows meters to be calibrated for certification.

Stick Features: Tailored arc control (DIG) allows the arc characteristics to be changed for specific applications and electrodes. Smooth running 7018 or stiffer, more penetrating 6010. Hot Start™ adaptive control provides positive arc starts without sticking.

Auto-Line Power Management Technology: Allows for any input voltage hookup (208 – 575 V) with no manual linking, providing convenience in any job setting. Ideal solution for dirty or unreliable power.

Cooler-On-Demand™: Feature operates the auxiliary cooling system only when needed, reducing noise, energy use, and airborne contaminants pulled through the cooler.

Upgradeable and Expandable: Front panel memory card data port provides the ability to easily upgrade software and expand product features.

Features of the Miller Dynasty 800

- Weldable Metals: Aluminum, Specialty Metals, Stainless Steel, Steel

- Material Thickness: Aluminum 0.020 in. (0.5 mm) – 1 in. (25.4 mm) – Steel 0.020 in. (0.5 mm) – 1 in. (25.4 mm)

- Input Phase: 1- and 3-Phase

- Amperage: 5 A (Min) – 800 A (Max)

So, what TIG welding machine is for you?

Well, my friend, this is for you to decide. Since we have explained these 5 machines in detail, you likely would want to get all of them. So, consult with your savings account before making up your mind here.

If you want some help here, feel free to contact us. Our consultants have decades of experience in dealing with TIG welding machines.