For any manufacturing company to have at least a light-duty plasma cutting table is a must. Especially in emerging economies where resources are scarce, to have the right equipment, to fulfill all the production needs, is essential for efficiency.

Now, what is exactly a light-duty plasma cutting table? What power source is needed? What are the steps to take if you are trying to get your first cutting table? We will answer all these questions in this article, starting with how to classify plasma cutting tables.

How to classify plasma systems

In the welding world, there is a clear difference between the equipment and it can be easily classified as light, medium, or heavy duty. In that field, equipment below 250 amperes, is light-duty. Equipment between 250 and 425 amperes, would be medium duty. Any equipment above 425 amperes would be considered heavy duty.

Nevertheless, when it comes to plasma cutting, the differences are not so established. Even thought, the metal sheets size, material, and thickness can be key factors to differentiate automated plasma cutting in three big groups: light, medium, and heavy duty. Let’s take a brief look to these factors.

The size

Metal sheets may come in a variety of sizes. One of the most common is 48 x 120 inches. This might vary depending on the availability in the country.

Before to deciding on a plasma cutting table you need to consider the metal sheet size available and needed for your production. Make sure the plasma cutting table you are thinking on buying can handle the metal sheets you are going to cut.

The material

There is a wide range of metals that can be cut in a light-duty plasma cutting table. Basically, using plasma you can cut any electrically conductively metal. Both ferrous (meaning that contains iron) and non-ferrous metals can be cut using plasma. Some of the most common materials to cut in a light-duty plasma cutting table are:

- Carbon steel

- Mild steel

- Stainless steel

- Expanded steel

- Copper

- Brass

- Aluminum

Chances are that the material you need to cut is among those. In particular the latter (aluminum) usually comes only in low thicknesses, so most likely you are going to use a light-duty plasma cutting table to handle that.

The thickness

Metal sheets and plates comes in a wide range of thicknesses. They can go from 0.02 inches (0.5 mm) to 6 inches (152 mm), even though these thicker metals are not so common. Usually, in fabrication, a metal plate is considered thick if is around 2-3 inches (51-76 mm). The rest are not common at all.

In any case, take into account the metal plate thickness you need to find out whether a light-duty plasma cutting table can do the job.

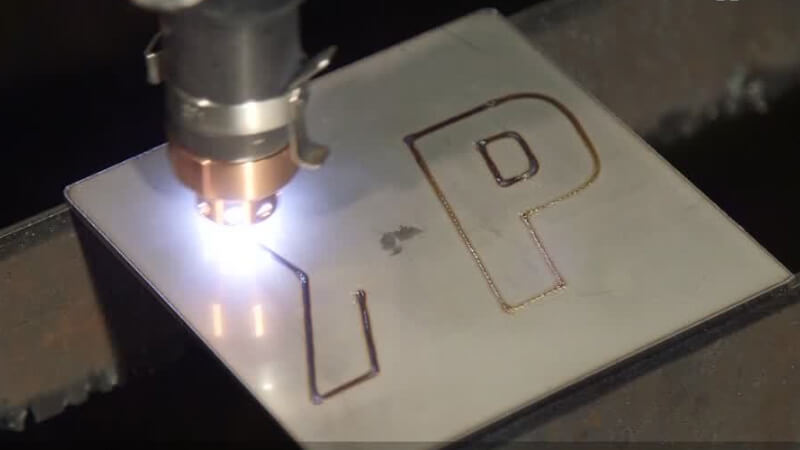

The cut quality

Another factor to take into account is the cutting quality. The more advanced cutting solutions would be able to provide a higher definition cut. So, if the workpieces are going to be cut in order to be weld, it is impotant an even cut, but high definition is not required. Now, if the cut is the final step, and is going to be exposed to the users, a higher definition is needed.

Finally, bear in mind that each cutting table can support some specific technologies. For example, you cannot expect that the simplest cutting table can be able to connect with the most advance power source, and achieve the highest cutting quality. Also, it would be a waste of money to get the more advanced cutting system to only perform basic cuts. So, your quality needs will also be key factors to define the adequate plasma cutting system for you.

What would be a light-duty plasma cutting table?

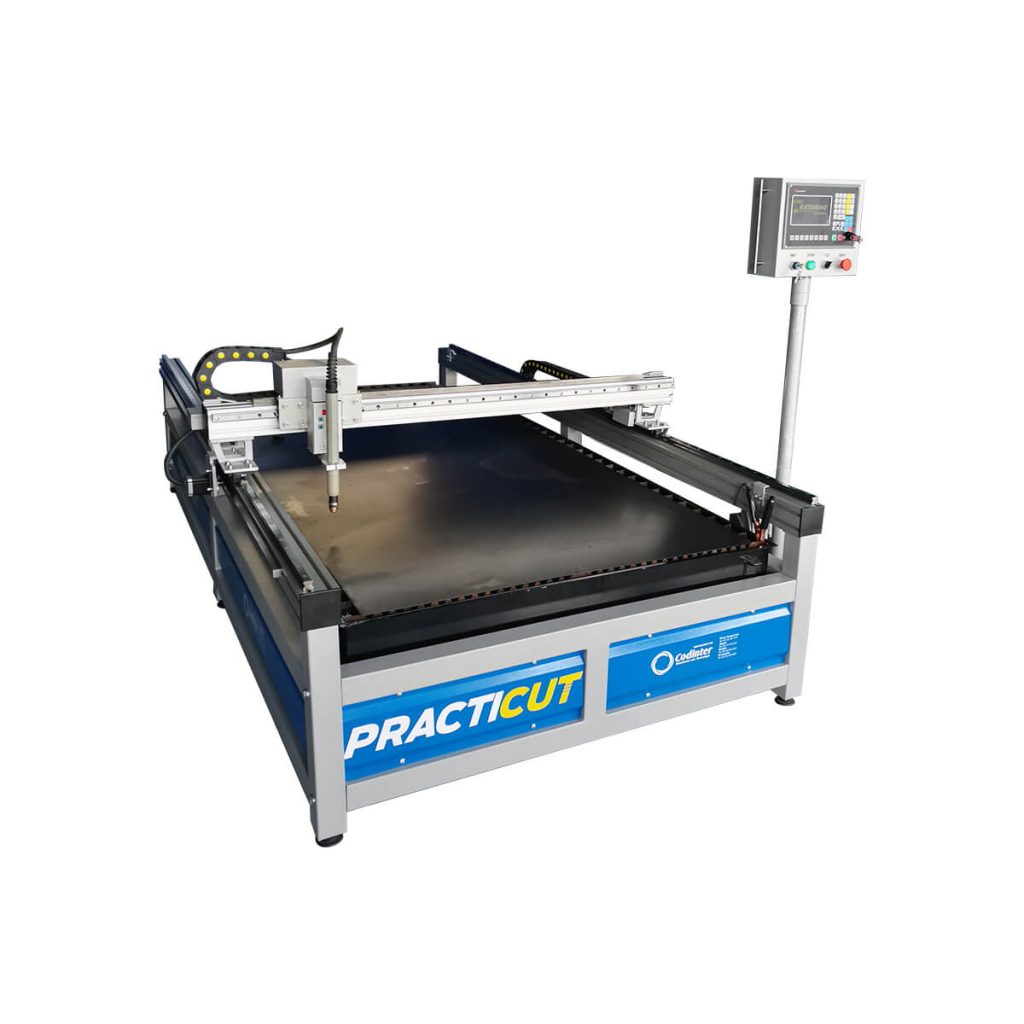

A small dimensioned plasma cutting table of a few feet wide could be properly defined as light-duty. This could be the first plasma cutting table a company might buy. One example in this category would be the Extreme Practicut. This plasma cutting table comes in a variety of sizes, like 4×8, 8×4, and 5×10 feet. The effective work area in this table could be 2,500x 1,250; 1,250×2,500; or 1,500×3000 mm respectively.

The manufacturers who need to cut aluminum or stainless steel (which usually are the thinner metal sheets) might need one plasma system like this. The ideal thickness for this cutting bracket could be up to ½ inch.

Some companies have welding and cutting carriages, which can also be considered as a light-duty plasma cutting system. In these cases, a portable carriage can be used to handle the torch that will cut the workpieces, especially when the job must be done outdoors, like in shipyards.

The most common power source for these light-duty plasma cutting system could be one of the Hypertherm Powermax. There is a range within this series. Later in this article we will introduce the Hypertherm Powermax45 SYNC, which is widely used as a power source in some light-duty plasma cutting systems.

We will cover medium-duty and heavy-duty plasma cutting systems in other articles. Stay tuned.

Plasma cutting table or plasma cutting system?

When we mention “cutting table” we are referring only to the metallic, sturdy base where the cutting operations take place. The table may come with a bridge or it can be gantry style, in which case it would be only a two sides structure with a top. If you have a plasma cutting table,regardless of its size, you only have part of the solution.

A plasma cutting system refers to the complete solution to perform metal cutting operations. It includes the table, a power source, a CNC (Computer Numeric Control), some software to manage the CNC, the cutting torches, and other accessories needed to perform.

Now, a plasma cutting system is not just assembled randomly. An expert is required to define the right power source, plasma cutting table, CNC, and software so the system can serve the purpose for what is built. If done incorrectly, a failure is expected at any moment.

Whatever the case, before getting any equipment is essential that an expert can overview the whole plan, including the are where the plasma cutting system is going to be put within the building.

Extreme Practicut

The Extreme Practicut is a cutting table that is available in 3 sizes: 4×8; 8×4, and 5×10 ft. It is a double motorized system that guarantees a better quality cut. With its space to store water, it manages to keep the pieces at a perfect temperature.

The Extreme Practicut cutting table contains divided pieces that make it easy to collect the cut pieces. In addition, the hole at the bottom can be connected to a space allowed to dispose of waste in a non-polluting way.

The system is composed of

- 7″ HD Color LCD screen

- Height sensor

- Compatible with multiple design programs

Basic features

- High resistance structure

- Beams built with high engineering

- Helical gears with adaptive movement

- Height control by plasma arc sensor

- Compact design structure built in steel / aluminum

- State-of-the-art CNC software

- FastCAM nesting program

- Link cable carrier system for protecting hoses and cables

- Automatic height sensor

- Universal interface for plasma

- 32 Mb memory, which supports Nesting

Technical specifications

- Power supply: 220 volts.

- Input current: 1A

- Internal fuse: 2A

- Input power: 200W

- Frequency: 50-60Hz

- Maximum speed: 6,000 mm/min.

- Screen: LCD 7″ Color

- Nesting Program: Fastcam

- Effective cut dimension: 1.22 x 2.44 Mt

- Table dimension: 2.22 x 3.44 Mt

- Work area: 2.28 x 5.88 Mt

- Accuracy: +/- 0.25mm

- Repeatability: 0.2mm

- Software compatible with: Autocad/Tekla/Solidworks

- Gross weight: 350 Kg

- Net weight: 180 Kg

FastCAM Software

FastCAM is a long established Australian software for shape cutting on sheet metal. FastCAM software is easier to use than other cutting systems. Editing is easy and geometry verification combined with a nesting step make this software instantly productive.

FastCAM software reads and edits DXF and DWG files. The FastNEST and FastPLOT functions support autonesting and allow to execute the code to verify respectively. FastCAM offers FastCAM drawing, FastNEST auto nesting, FASTPATH auto pathing, and FastPLOT verification.

Pathing, true form nesting, code verification and NC generation make this software the most complete low cost solution for profile cutting. Even on large and complex construction jobs, where heavy plates are used, the FastCAM software works flawlessly.

Hypertherm Powermax45 XP

The Powermax45® XP plasma cutter delivers increased cut capacity – up to 16 mm (5/8″) metal – as well as faster cut speeds, and automatic gas adjustment for quick, simple setup and operation.

Duramax® Lock torches support handheld and mechanized cutting of a wider range of metal thicknesses, along with precision gouging such as spot weld removal, and marking capabilities.

It’s easy to use

- Small size and light weight provide exceptional portability for a 16 mm (5/8″) rated cutting system

- Patented drag-cutting technology makes the Powermax45 XP easy to use – even for first-time operators

- Smart Sense™ technology ensures that air pressure is always correctly set.

Outstanding versatility

- CNC interface and FastConnect™ torch connection allows both handheld and mechanized operation

- A wide range of torch and consumable styles to choose from for both handheld and automated processes

- Extensive array of application capabilities via specialty consumables for fine feature cutting, extended reach cutting, gouging, precision gouging, and marking

Maximum productivity

- Finish jobs faster, with cut speeds 1.5 times greater than oxyfuel on 6 mm (1/4″) mild steel

- Superior cut and gouge quality reduces time for grinding and edge preparation

- New torch disable switch feature allows faster, easier changeout of consumables

Rugged and reliable

- Duramax® Lock torches are designed for high-impact and heat resistance

- SpringStart™ technology ensures consistent starting and optimum torch performance

- Hypertherm Certified™ reliability ensures peak performance even in the most demanding environments

Powermax Duramax Lock torches

- Designed for low environmental impact

- Plasma cutting efficiency is 11% better than its predecessor, enabling you to cut more steel with less power, in less time

- All plasma system components are recyclable

- 14% lighter than its predecessor and delivers more cutting power

Hypertherm Powermax Product Line

For metal workers who need to easily and reliably gouge and cut metal up to 38 mm (1-1/2″), Powermax® is a line of seven portable, professional-grade plasma systems that are designed for maximum productivity.

Unlike other metal removal methods or competitive plasma brands, industry-leading Powermax systems allow customers to tackle any job by offering the most extensive manual and automated metal cutting and gouging capabilities.

When light duty is not enough

As we stated before, plasma cutting systems can be grouped as light, medium and heavy duty based on the size, work cycle, and cut quality. Any of these needs might be the reason why you would need to move from a light-duty plasma cutting table to something with more capacity.

Many companies make a careful review of their equipment when is time to upgrade them. Whether that is your case, or you are trying to get a light-duty plasma cutting table for the first time, we are here to help We have decades of experience helping companies to get the right industrial equipment, including plasma cutting systems.